| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

|

|

| Semi-Finished Lighters Parts | Lighters Assembly Lines |

| Electronic Lighters Lines | Lighters Production Lines |

Pimpex@RPM's partner factory is a high-tech enterprise, focusing on intelligent manufacturing and automation equipments research, development and sales. We do research and development, sell and offer after-services on the lighters, hardware products, automation equipments, we have formed a complete chain system on lighter industry, professionally researched and developped lighter-industry equipments for 16 years, we are also the leader of automation equipments in China's lighter industry. Pimpex@RPM presents lighters production process here, which is suitable for various lighter types including flint lighter, grinding wheel lighter, electronic lighter, windproof electronic lighter, etc. |

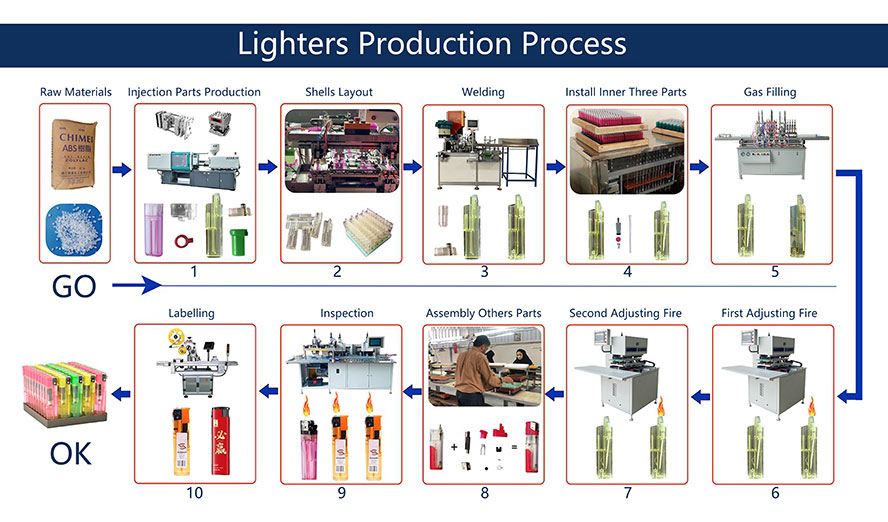

Lighters Production Process |

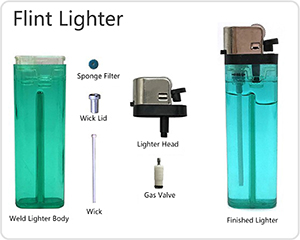

01 Lighter Type Flint Lighter, Grinding Wheel Lighter |

02 Lighter Type Electronic Lighter |

03 Lighter Type Windproof Electronic Lighter |

Here is the intro of necessary equipments/facilities for lighters plastic accessories production: injection molding machine, lighter body/shell molds, lighter inner head molds, and supporting auxiliary equipments like cold water tower, flashes crushing and recycling machine, manipulator, conveyer belt, complete set of air compressor equipments.

By the way, only after a client's output/demand of assemblying lighters reaches 10 millions pcs monthly, it is the time that the client could consider to invest on injection machines/molds, welding machines, etc.

09 Lighters Plastic Accessories Production Injection Molding Machine Supporting Auxiliary Equipments Cold Water Tower |

10 Lighters Plastic Accessories Production Injection Molding Machine Supporting Auxiliary Equipments Flashes Crushing and Recycling Machine |

11 Lighters Plastic Accessories Production Injection Molding Machine Supporting Auxiliary Equipments Manipulator |

||||||||||||||||||||||||||||||

12 Lighters Plastic Accessories Production Injection Molding Machine Supporting Auxiliary Equipments Conveyer Belt |

|

|||||||||||||||||||||||||||||||

13 Lighters Plastic Accessories Production Complete Set of Air Compressor Equipments |

|

|||||||||||||||||||||||||

Pimpex@RPM supplies lighters production lines, including fully automatic lighter body/shells layout typesetting and sorting machine; automatic welding machine for welding lighter body/shell, inner head, bottom cover, small screw, sleeve and other accessories; assembly line to install zinc sleeves, wicks, cotton chips, valves into semi finished lighters; automatic filling gas machine to charge butane gas via dosing cylinder by fully pneumatic control; automatic adjusting fire machine to adjust fires twice, 12 hours apart, to same fire height; flint lighter assembly line to install finished lighter head to flame adjusted semi finished lighter body and snap flame plate onto face valve; electronic lighter assembly line to install electronics, buttons, windshield to flame adjusted semi finished lighter body to complete assembly of entire electronic lighter; automatic inspection machine performs final flame height detection and detects flameout phenomenon on finished lighters; labeling machine or paper wrapping machine to deal with appearance of lighters.

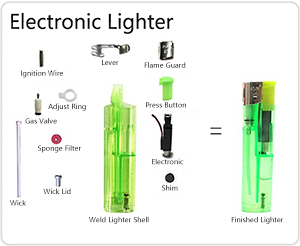

14 Fully Automatic Lighter Body/Shell Layout Typesetting Machine and Sorting Machine a |

After the injection molding machine produces lighter shells, which will be very messy when they come out of the mold. They need to be arranged neatly and inserted into the production turnover base (which can hold 50 lighters) to facilitate subsequent automated production.

|

||||||||||||||||

15 Automatic Welding Machine for Welding Lighter Body/Shell, Inner Head Bottom Cover, Small Screw, Sleeve Other Accessories a |

15 Automatic Welding Machine for Welding Lighter Body/Shell, Inner Head Bottom Cover, Small Screw, Sleeve Other Accessories b |

The lighter shell must be welded with the inner head, bottom cover, small screw sleeve and other accessories through ultrasonic waves welding to achieve the effect of sealing the butane gas.

|

||||||||||||||||||||||||

16 Assembly Line to Install Zinc Sleeves, Wicks, Cotton Chips, Valves into Semi Finished Lighters a |

16 Assembly Line to Install Zinc Sleeves, Wicks, Cotton Chips, Valves into Semi Finished Lighters b |

Install the four accessories of zinc sleeve, drainage core, cotton sheet and face valve to the welded lighter semi-finished product.

|

||||||||||||||||

17 Automatic Filling Gas Machine to Charge Butane Gas via Dosing Cylinder by Fully Pneumatic Control |

Automatic Filling Gas Machine inflates butane gas into the lighter casing shell through a quantitative cylinder. Each station uses an independent quantitative cylinder to inflate, which can accurately control the butane gas volume of each lighter. The equipment adopts full pneumatic control method, without using electric voltage, ensuring the safety of production.

|

||||||||||||||||||||||||

18 Automatic Adjusting Fire Machine to Adjust Fires Twice 12 Hours Apart to Same Fire Height |

Due to errors in the lighter accessories, the flame height of the lighter cannot be unified after inflation, and cannot meet product quality requirements. The flame height must be adjusted to a unified height. Moreover, it is necessary to adjust the fire twice. The first and second fire adjustment need to be separated by at least 12 hours. It is recommended to perform the second fire adjustment at an interval of 24 hours to ensure the stability of the quality.

|

||||||||||||||||||||||||

19 Flint Lighter Assembly Line to Install Finished Lighter Head to Flame Adjusted Semi Finished Lighter Body and Snap Flame Plate onto Face Valve a |

19 Flint Lighter Assembly Line to Install Finished Lighter Head to Flame Adjusted Semi Finished Lighter Body and Snap Flame Plate onto Face Valve b |

Install the finished outer lighter head to the semi-finished lighter with the flame adjusted, and snap the flame plate onto the face valve to complete the assembly of the entire lighter.

|

||||||||||||||||

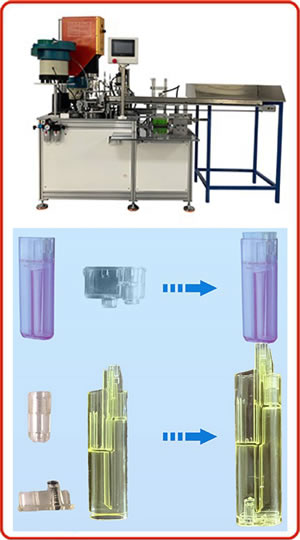

20 Electronic Lighter Assembly Line to Install Electronics Buttons Windshield to Flame Adjusted Semi Finished Lighter Body to Complete Assembly of Entire Electronic Lighter a |

20 Electronic Lighter Assembly Line to Install Electronics Buttons Windshield to Flame Adjusted Semi Finished Lighter Body to Complete Assembly of Entire Electronic Lighter b |

Install several accessories such as electronics, buttons, and windshield to the flame-adjusted semi-finished lighter to complete the assembly of the entire lighter.

|

||||||||||||||||

21 Automatic Inspection Machine Performs Final Flame Height Detection and Detects Flameout Phenomenon on Finished Lighters a |

21 Automatic Inspection Machine Performs Final Flame Height Detection and Detects Flameout Phenomenon on Finished Lighters b |

After all the parts of the lighter are assembled into the finished lighter, although the flame size has been adjusted earlier by the lighter fire adjusting machine, due to errors in the parts and changes in the flame during the assembly process, an inspection machine is required to perform final flame height detection on the finished lighter. The detection of fire failure ensures the final quality of the lighter, and the inspection machine is an indispensable testing equipment.

|

||||||||||||||||

22 Labeling Machine Paper Wrapping Machine to Deal with Appearance of Lighters a |

22 Labeling Machine Paper Wrapping Machine to Deal with Appearance of Lighters b |

After the lighter completes the final inspection, the appearance of the lighter needs to be processed. The most commonly used methods are labeling and wrapping the entire lighter.

|

||||||||||||||||||||||||

23 Visits of Customers to Factory of Lighers Production Lines |

24 Leaders Investigations to Factory of Lighers Production Lines |

25 Media Report on Factory of Lighers Production Lines |

|

||

|

|

|

|

|

||

| rubberimpex.com | plasticimpex.com | mouldimpex.com | Loowi.com | GoldenPalaceGate.com | ||

| rubberplasticmould.com | ibmmachine.com |

moldimpex.com |

iLoowi.com | GoldenPalaceGate.cn | ||

| rpm.mobi | isbmmachine.com | masks machines | jindianmen.cn | |||

| wastetiresrecycle.com | printing-machines.cn | hot-stamping-machines.cn | hot-stamping-machines.com | logistics-forklifts.cn |

| Copyright © Pimpex@RPM Since 2002 www.plasticimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |