01 Technical Meeting for

Electronic Lighters Production Line |

02 Office of Manufacturer for

Electronic Lighters Production Line |

03 Electronic Lighter Production Line

in Customer Factory |

04 Lighter Gas Filling Machine

1 Filling 20 |

05 Flint Lighter Production Line

|

06 Customer Factory 10 Lighters

|

07 Lighter Flame Adjustment Machine |

08 Lighter Head Assembly Machine |

09 Updated Automatic Lighters Production Line |

10 Automatic Picking Out Machine

for Defects of Lighters |

11 Assembling Nozzles of Lighters

|

12 Lighters Flame Adjustment Machine

1 Adjust 20 |

13 Automatic Lighter

Ultrasound Welding Machine FTHJ1

for Lighters Screw Sleeve and Bottom Valve Welding |

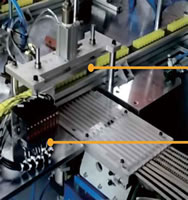

14 Automatic Lighter

Ultrasound Welding Machine FTHJ10

|

15 Automatic Lighter

Ultrasound Welding Machine FTHJ10

Ultrasonic Welding Head |

16 Automatic Lighter

Ultrasound Welding Machine FTHJ10

Automatic Loading and Unloading

with Dual Manipulators |

17 Automatic Lighter

Ultrasound Welding Machine FTHJ10

Welding Inflatable Bottom Valve

High Quality Optical Fiber Amplifier |

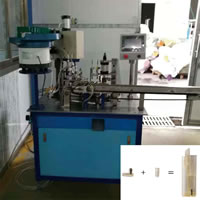

18

Automatic Lighter

Nozzle Assembly Machine

FTMF200 |

19 Automatic Lighter

Nozzle Assembly Machine FTMF200

Screening Machine |

20 Automatic Lighter

Nozzle Assembly Machine FTMF200

Lighter Nozzle Making Host Machine |

21 Automatic Lighter

Nozzle Assembly Machine FTMF200

Good Insulation High Precision Board

for Plate Parts |

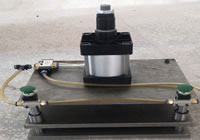

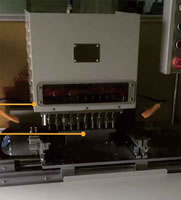

22 Automatic Pneumatic Lighter

Gas Filling Machine

FTCQ05 |

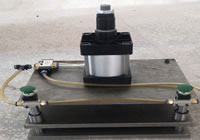

23 Automatic Pneumatic Lighter

Gas Filling Machine FTCQ05

Air Cylinder |

24 Automatic Pneumatic Lighter

Gas Filling Machine FTCQ05

High Precision

Synchronous Belt and Synchronous Wheel |

25 Automatic Pneumatic Lighter

Gas Filling Machine FTCQ05

Infinite Variable Speed Motor

|

26

Microcomputer Lighter

Flame Adjustment Machine

FTTH10 |

27 Microcomputer Lighter

Flame Adjustment Machine FTTH10

Transparent Isolation Design Scheme

for Flames and Lighters |

28 Microcomputer Lighter

Flame Adjustment Machine FTTH10

Easy Replacement Among Models |

29 Microcomputer Lighter

Flame Adjustment Machine FTTH10

Good Appearance Design 1 |

30 Microcomputer Lighter

Flame Adjustment Machine FTTH10

Good Appearance Design 2 |

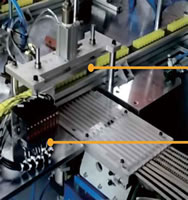

31 Automatic Lighters

Heads Assembly Machine FTFBS200

Flint Style

- |

32 Automatic Lighters

Heads Assembly Machine FTFBS200

Flint Style

Finished Lighters Heads Screening Machine |

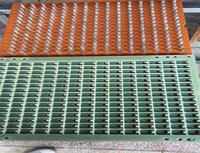

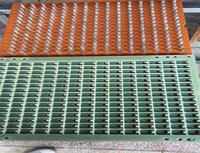

33 Automatic Lighters

Heads Assembly Machine FTFBS200

Flint Style

Finished Lighters Heads Screening Plate |

34 Automatic Lighters

Heads Assembly Machine FTFBS200

Flint Style Lighters Positioning Plate |

35 Automatic Lighters

Heads Assembly Machine FTFBS200

Flint Style Lighters Carriage Plate |

36 Automatic Lighters

Heads Assembly Machine FTFBS200

Flint Style Pry Plate Press Lever |

37 Automatic Lighters

Heads Assembly Machine FTFBS200

Flint Style Finished Lighters Heads Press |

|

|

38 Automatic Lighter Flip Assembly Machine

FTFBZ200 |

39 Automatic Lighter Flip Assembly Machine

FTFBZ200 Press |

40 Automatic Lighter Flip Assembly Machine FTFBZ200

Screening Machine |

41 Automatic Lighter Flip Assembly Machine

FTFBZ200 Windcover Sieve Plate |

42 Automatic Lighter Flip Assembly Machine

FTFBZ200 Pry Plate Sieve Plate |

43 Automatic Lighter Flip Assembly Machine

FTFBZ200 Button Sieve Plate |

44 Automatic Lighter Flip Assembly Machine

FTFBZ200 Electronic Sieve Plate |

45 Automatic Lighter Flip Assembly Machine

FTFBZ200 Fire Ring Sieve Plate |

46 Automatic Lighter Flip Assembly Machine

FTFBZ200 Ignition Spring Sieve Plate |

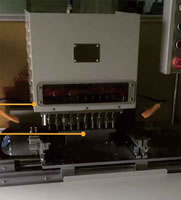

47 Automatic Lighter Inspection Machine

FTJY10 |

48 Automatic Lighter Inspection Machine

FTJY10 Flame Height Inspection System |

49 Automatic Lighter Inspection Machine

FTJY10 One Staff One Machine |

50 Automatic Lighter Inspection Machine

FTJY10 Smart Troubleshooter |

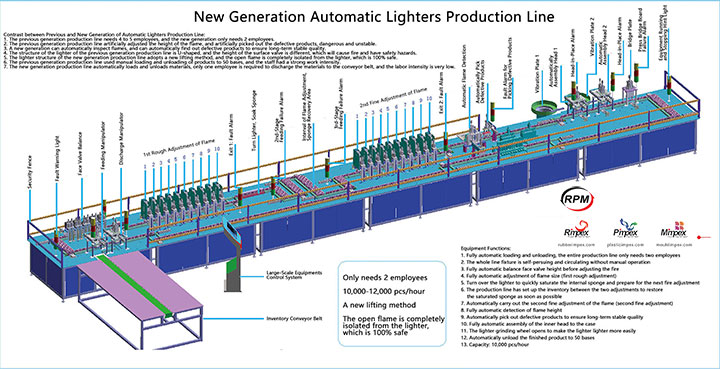

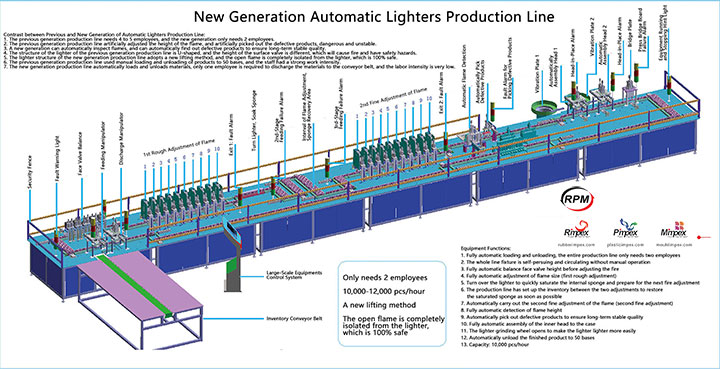

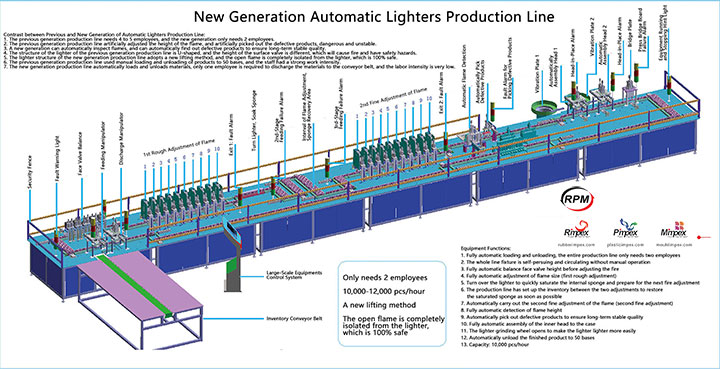

51 New Generation

Automatic Lighters Production Line |

52 New Generation

Automatic Lighters Production Line

New Lifting Method for Flame Adjustment |

53 New Generation

Automatic Lighters Production Line

Conveying Belt |

54 New Generation

Automatic Lighters Production Line

Automatic Flame Adjustment |

55

Customer of Lighters Production Line

a |

56 Customer of Lighters Production Line

b |

57 Customer of Lighters Production Line

c |

58 CE Certificate of

Lighters Production Equipments |

59 Patent of

Lighter Blank Screw Slack Adjustment Equipment

for Looseing Valve Process |

60 Automatic

Fire Detection and Adjustment Equipment

for Lighters |

61 Automatic

Fire Detection and Adjustment Equipment

for Lighters |

Lighter blank screw slack adjustment equipment

A blank screw slack adjustment equipment developed for the loosening-valve process of the lighter industry.

Technological Breakthrough:

1. Automation: The process of loosening the valve realizes fully automatic operation.

2. High efficiency: 60,000 valves are loosened daily, which is 20 times that of manual operation.

3. Wide application: meet the application of multiple types of lighters. |

Automatic Lighter Adjustment Scheme

An automatic fire detection and adjustment equipment for lighters, through self-judgment of the flame height, screens out unqualified products, and at the same time shifts the adjustment ring to the middle place, saving manual processes.

Technical Breakthrough:

1. Convenience: The process of fire inspection requires only manual loading and unloading, which is simple, convenient and easy to operate.

2. High efficiency: One production line can produce 8,000 to 9,000 lighters per hour, and can meet the requirement of continuous production of 24 hours, which greatly improves the production efficiency.

3. Safety: Automatic lock when power failure, power overload protection, air pressure overload protection, and sound, electricity, light, and fault warning systems to ensure equipment operation and personnel safety. |

|

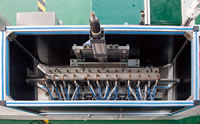

14 Automatic Lighter

Ultrasound Welding Machine FTHJ10

|

Device Parameters:

Sizes: L2.2m*W2m*H1.2m

Voltage: AC22OV

Air Pressure: O.6MP

Weight: 260kgs

Device Model: FTHJ10

Capacity: 112,000pcs/hour

Operating Staff: 1

Device Functions:

This equipment is designed with a reasonable work flow, and the incoming and outgoing materials are in the same direction, saving employees' walking time and reducing their labor intensity. In terms of control system, the new use of intelligent manufacturing technology, deep self learning big data advantage, when a certain station of the equipment fails, the touch control system will prompt and tell the maintenance personnel to deal with it, saving maintenance personnel's blindly repairing, the fastest time to solve problem, greatly save time and increase equipment utilization to maximization to ensure production output.

Process Description:

1. The injection molded case must be stored for more than 12 hours before welding.

2. Use the welding machine to weld ten pcs at a time, the inner head's buckle should be welded about 2.5mm in height, and the welding line is controlled at 1.1mm to 1.2mm.

3. If it is to weld inflatable lighter, the bottom valve welding line should be controlled at 0.9mm to 1mm.

|

15 Automatic Lighter

Ultrasound Welding Machine FTHJ10

Ultrasonic Welding Head |

16 Automatic Lighter

Ultrasound Welding Machine FTHJ10

Automatic Loading and Unloading

with Dual Manipulators |

17 Automatic Lighter

Ultrasound Welding Machine FTHJ10

Welding Inflatable Bottom Valve

High Quality Optical Fiber Amplifier |

Brand new ultrasonic welding head, after 15 years of research, we have a lot of experience data. The original welding head can only be used for 1 2 months, and now one welding head can easily be used for 6 months.

The black part of the welding head adopts a special process. |

The equipment adopts double manipulators for fully automatic loading and unloading, which can be easily operated by one person. The quality of products is more stable than traditional manual welding, and the efficiency is more than 10 times higher than that of traditional manual welding. |

The inflatable bottom valve is also completed on the same line. When the inflatable bottom valve does not need to be welded, it can be turned off on the control touch system. It is very simple without other complicated operations.

Use high quality optical fiber amplifiers to test each accessory to ensure that there are 100% no missing accessories. |

|

22 Automatic Pneumatic Lighter

Gas Filling Machine

FTCQ05 |

Device Parameters:

Sizes: L1.5m*1m*0.8m

Power: no electric, pure pneumatic

Air Pressure: 0.6MP

Device Model: FTCQ05

Weight: 270kgs

Capacity: 8000 9000 pcs/hour

Operating Staff: one person, one machine

Equipment Functions:

The working cylinder of the equipment adopts a large cylinder, which has large bearing capacity, uniform strength, stable work, stable stroke and more durable. It adopts precise timing belt and timing wheel as transmission mechanism, which has higher precision and more stable operation. The lead motion uses the Taiwan Shangyin large slider, which has high precision and no gap. It can be used for more than five years to ensure worry free.

Process Description:

1. First, self check whether the surface valve is tight or crooked or locked.

2. Add gas quantitatively according to quality requirements/standards.

3. The defective products produced during the inflation process such as semi gas, excessive gas, crooked needle, shrunk needle and no gas should be selected out. |

23 Automatic Pneumatic Lighter

Gas Filling Machine FTCQ05

Air Cylinder |

24 Automatic Pneumatic Lighter

Gas Filling Machine FTCQ05

High Precision

Synchronous Belt and Synchronous Wheel |

25 Automatic Pneumatic Lighter

Gas Filling Machine FTCQ05

Infinite Variable Speed Motor

|

| The working cylinder of the equipment adopts a large cylinder, which has large bearing capacity, uniform strength, stable work, stable stroke and more durable. |

Using precise timing belt and timing wheel as transmission mechanism, higher precision and more stable operation. |

The power source adopts a stepless variable speed motor, which always moves in the same direction. The face valve is more uniform and the force is more uniform, ensuring that the height of the screwed face valve is consistent and the quality is guaranteed. |

|

26 Microcomputer Lighter

Flame Adjustment Machine

FTTH10 |

Device Parameters:

Sizes: L1.4m*W0.8m*H1.2m

Voltage: AC220V

Air Pressure: 0.6MP

Weight: 245kgs

Power: 1350W

Device Model: FTTH10

Capacity: 7000 8000 pcs

Operating Staff: one person, one machine

Equipment Functions:

The main function of the lighter is to adjust the inflated lighter flame to the same size.

|

27 Microcomputer Lighter

Flame Adjustment Machine FTTH10

Transparent Isolation Design Scheme

for Flames and Lighters |

28 Microcomputer Lighter

Flame Adjustment Machine FTTH10

Easy Replacement Among Models

|

29.30 Microcomputer Lighter

Flame Adjustment Machine FTTH10

Good Appearance Design |

| When the machine is working, you can observe the size of the flame through the fully sealed transparent window. We adopt a 100% isolation design scheme between the flame and the lighter. No matter which process causes the quality problem, there is no danger in the fire control, even in case of the entire lighter bursts or the surface valve runs away. We can truly achieve 100% safety and reliablity. |

To change the model, you only need to easily click on the touch screen to change the model. All the data devices are automatically adjusted to the corresponding model, and each model change takes only one minute. |

Our equipment is not only stable and safe, but also a lot of attention has been paid to appearance design, which not only guarantees production output, production safety, and simple maintenance, but also adds good impression on factory's appearance. |

|

38 Automatic Lighter Flip Assembly Machine

FTFBZ200 |

Device Parameters:

Sizes: L6m*W4m*H1.2m

Voltage: AC220V

Air Pressure: 0.6MP

Weight: 360kgs

Device Model: FTFBZ200

Capacity: 1-1.2 million pcs/hour

Operating Staff: 6

Equipment Functions:

The flap is to arrange the parts of the lighter with the vibration of the sieve, and then put the parts into the lighter casing through the flap, sliding plate and pressing plate. This method is simple, high in output and easy to operate. The investment cost is much less than that of the automatic production line. Only the corresponding plate is replaced when the model is changed. Other screens and presses are common, which greatly reduces the production cost.

Process Description:

1. Go to the warehouse to receive the corresponding accessories after the repeated confirmation according to the order requirements.

2. The turnover plate production process firstly screens the gaskets, inserts the ignition springs, screens the outer heads, screens the fire rings and the bridge plates, places the electronics, places the pressure cover (hand press) and the air hoods.

3. In the production process, there must be no missing parts, no lacking parts or no bad parts. |

39 Automatic Lighter Flip Assembly Machine

FTFBZ200 Press |

40 Automatic Lighter Flip Assembly Machine FTFBZ200

Screening Machine |

|

41 Automatic Lighter Flip Assembly Machine

FTFBZ200 Windcover Sieve Plate |

42 Automatic Lighter Flip Assembly Machine

FTFBZ200 Pry Plate Sieve Plate |

43 Automatic Lighter Flip Assembly Machine

FTFBZ200 Button Sieve Plate |

44 Automatic Lighter Flip Assembly Machine

FTFBZ200 Electronic Sieve Plate |

45 Automatic Lighter Flip Assembly Machine

FTFBZ200 Fire Ring Sieve Plate |

46 Automatic Lighter Flip Assembly Machine

FTFBZ200 Ignition Spring Sieve Plate |

47 Automatic Lighter Inspection Machine

FTJY10 |

Device Parameters:

Sizes: L2.35m*W1.20m*H1.55m

Voltage: AC220V

Air Pressure: 0.6MP

Power: 2750W

Weight: 350kgs

Device Model: FTJY10

Capacity: 8000-9000 pcs/hour

Operating Staff: One Person, One Machine

Equipment Functions:

The equipment is loaded and unloaded with a robot for automatic loading and unloading. The intelligent system can automatically fine-tune the fire ring according to the process requirements to reach the required flame size, and automatically pick out the defective products to ensure that there are no defects in the qualified products after inspection. Long-term good quality could be ensured.

Process Description:

1. Match the fixture according to the model.

2. Debug the machine according to customer needs and quality requirements (flame height, ignition rate).

3. After 200 pieces are produced in the experiment, 100 pieces are self-inspected, and then 100 pieces are passed for quality inspection before mass production.

Inspection Notes:

1. Operate in accordance with the requirements of the order and the inspection method provided by the quality department.

2. Before starting the fire, take the integrated fire and check to see if there are any lack of air, air leakage and no air, and select out defective products with defects in appearance.

3. Set the inspection machine to the standard flame height according to the order requirements, and operate according to the normal requirements for three consecutive fires or two of three consecutive fires (specifically based on customer needs). |

48 Automatic Lighter Inspection Machine

FTJY10 Flame Height Inspection System |

49 Automatic Lighter Inspection Machine

FTJY10 One Staff One Machine |

50 Automatic Lighter Inspection Machine

FTJY10 Smart Troubleshooter |

| The equipment is equipped with a flame height monitoring system to keep track of the quality of the lighter at any time.

At the same time, there are different quality requirements and options to meet customers' quality requirements. |

One machine per person, low work intensity, high output and more stable quality. |

The equipment writes intelligent programs, and if the equipment suddenly stops or malfunctions, the control screen will have corresponding prompts, reducing troubleshooting time, reducing equipment maintenance time, increasing output, and repairing equipment without professionals if possible. |

|

51 New Generation

Automatic Lighters Production Line |

Device Parameters:

Sizes: L9.8m*W1.2m*H1m

Voltage: AC220V

Air Pressure: 0.6MP

Weight: 1830kgs

Capacity: 10,000-12,000 pcs/hour

Operating Staff: 4

Equipment Functions:

The automatic production line features a complete automatic line with automatic loading and unloading, two automatic adjustments, and automatic pressing of the outer head of the finished product. The two adjustments are automatically completed by the equipment, and no manual operation is required to improve production. The safety and continuity of the product greatly reduces the number of employees. It does not need to control the quality manually, but uses the equipment to control the quality by itself, with fewer people, higher output, and more stable product quality.

1. Fully automatic loading and unloading, the entire production line only needs two employees

2. The whole line fixture is self-persuing and circulating without manual operation

3. Fully automatic balance face valve height before adjusting the fire

4. Fully automatic adjustment of flame size (first rough adjustment)

5. Turn over the lighter to quickly saturate the internal sponge and prepare for the next fire adjustment

6. The production line has set up the inventory between the two adjustments to restore the saturated sponge as soon as possible

7. Automatically carry out the second fine adjustment of the flame (second fine adjustment)

8. Fully automatic detection of flame height

9. Automatically pick out defective products to ensure long-term stable quality

10. Fully automatic assembly of the inner head to the case

11. The lighter grinding wheel opens to make the lighter lighter more easily

12. Automatically unload the finished product to 50 bases

13. Capacity: 10,000 pcs/hour

Process Description:

Find the matching fixtures according to the model to be produced, and then debug the other parts of the machine, such as inserting the springs, debugging the flame and other parts, assembling the finished product head parts and the pressure bridge parts.

Contrast between Previous and New Generation of Automatic Lighters Production Line:

1. The previous generation production line needs 4 to 5 employees, and the new generation only needs 2 employees.

2. The previous generation production line artificially adjusted the height of the flame, and artificially picked out the defective products, dangerous and unstable.

3. A new generation can automatically inspect flames, and can automatically find out defective products to ensure long-term stable quality.

4. The structure of the lighter of the previous generation production line is U-shaped, and the height of the surface valve is different, which will cause fire and have safety hazards.

5. The lighter structure of the new generation production line adopts a new lifting method, and the open flame is completely isolated from the lighter, which is 100% safe.

6. The previous generation production line used manual loading and unloading of products to 50 bases, and the staff had a strong work intensity.

7. The new generation production line automatically loads and unloads materials, only one employee is required to discharge the materials to the conveyor belt, and the labor intensity is very low. |

52 New Generation

Automatic Lighters Production Line

New Lifting Method for Flame Adjustment |

53 New Generation

Automatic Lighters Production Line

Conveying Belt |

54 New Generation

Automatic Lighters Production Line

Automatic Flame Adjustment |

| The lighter structure of the production line adopts a new lifting method, and the open flame is completely isolated from the lighter, which is 100% safe. |

The conveyor belt automatically transports the lighters, high efficiency, fast and stable. |

Ten lighters can be adjusted at one time on the automatic line, with high efficiency and automatic fire control, which is safe and stable. |

|