| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

|

|

Pimpex@RPM supplies masks making machines which could be customized, such as automatic N95 masks making machines, automatic KN95 masks making machines, 3M automatic cup type masks making machines with sponge strips, automatic KF94 fish shaped masks making machines, automatic flat masks making machines, etc.

3M Automatic Cup Type Masks Making Machine with Sponge Strips 10-15pcs per Minute |

01 Automatic N95 Masks KN95 Masks Making Machine 120-130pcs per Minute Bus Servo Structure, Stable Performances Welcome Customization |

02 Automatic N95 Masks KN95 Masks Making Machine 120-130pcs per Minute Bus Servo Structure, Stable Performances Welcome Customization |

03 Automatic N95 Masks KN95 Masks Making Machine 120-130pcs per Minute Bus Servo Structure, Stable Performances Welcome Customization |

04 Automatic N95 Masks KN95 Masks Making Machine 120-130pcs per Minute Bus Servo Structure, Stable Performances Welcome Customization |

2. The pneumatic + bus servo control system is adopted, and the key structural parts adopt servo control (2 servos for the nose bridge, 8 servos for the welding earbands, 2 servos for the edge banding, 1 servos for the spindle). Automatic N95 Masks KN95 Masks Making Machine has stable performance, faster speed and high productivity; 3. The system of Automatic N95 Masks KN95 Masks Making Machine is newly optimized and upgraded, simpler and more user-friendly, convenient for employees to operate, and quick to get started. 4. Our company provides system training, high-quality after-sales service for Automatic N95 Masks KN95 Masks Making Machine, customers can quickly put into production, and there is no worries about buying the machine. |

|

01 Automatic N95 Masks KN95 Masks Making Machine 120-130pcs per Minute Bus Servo Structure, Stable Performances Welcome Customization Blue |

02 Automatic N95 Masks KN95 Masks Making Machine 120-130pcs per Minute Bus Servo Structure, Stable Performances Welcome Customization Blue |

03 Automatic N95 Masks KN95 Masks Making Machine 120-130pcs per Minute Bus Servo Structure, Stable Performances Welcome Customization Blue |

Parameter Requirements and Appearance of N95 Masks and KN95 Masks

Mask Parameters (the mask version is to be confirmed separately, and the sample should be signed as approval)·Expansion Width of N95 Mask and KN95 Mask: 230mm ·Embossed Words: "N95" or "KN95", other requirements could be customized, our company provides technical consultation services. ·Earband Ultrosonic Welding: Subject to the position of the welding point of the knurled earband. |

||

Description on Sizes and Appearance: |

| N95/KN95 Automatic High-Speed Masks Machine | ||||

| Structure | L*W*H | Packing Size, mm | Net Weight, kgs | Remarks |

| Rack | 2220*670*1740 | 2350*950*2020 | 150 | The packing sizes given in this table are estimated, and the actual logistics company shall prevail according to the transportation method. |

| Front Section | 2085*1130*1550 | 2300*1000*1900 | 750 | |

| Rear Section | 2200*1460*1500 | 2400*1300*1730 | 850 | |

| Total Net Weight | 1750 | Weight without packaging (wooden crates) | ||

| Main Configuration & Technical Specifications of Automatic N95 Masks KN95 Masks Making Machine | ||

| Electrical Components | Controller | XINJE |

| HMI | XINJE 7" Colorful Touch Screen | |

| Sensor | OMRON | |

| Earband Rotating Motor | 400W Servo Motor | |

| Ultrasonic Wave | CONPROFE | |

| Welding Servo | INJE or HCFA | |

| Pneumatic Components | Clampping Cylinder | AirTAC |

| Solenoid Valve | AirTAC | |

| Oil-Water Separator | China Origin | |

| Product Specifications | Mask Specifications | N95/KN95 Edge Sealed) |

| Earband Length | 180-220mm | |

| Welding Spots Spacing | Adjustable from 50mm to 55mm | |

| Welding Spot Size | 8*12MM, Confirmed by Drawings | |

| Welding Time | 100-200ms | |

| Equipment Specifications | Welding Method | Continuous/Instant Welding |

| Program Storage | Simple & Adjustable | |

| Operation Safety Protection | Emergency Stop | |

| Action Protection | Software Action Interlock | |

| Operating Height | 1200mm | |

| Operating Environment | Ambient temperature does not exceed 40℃, no flammable nor corrosive gas, no dust (cleanness is not below 100,000 level. |

|

| Air Pipe Specifications | D12mm 2pcs | |

| Air Supply | 0.5~0.7MPa Dry Air Source/20L/min | |

| Power Specifications | AC 220V/380V 50/60Hz±10% | |

| Input Power | 20kW | |

| Equipment Weight | About 1750kgs | |

| Overall Dimensions | L6500mm*W1500mm*H1750mm | |

| Technical Parameters of Materials for KN95 Masks and N95 Masks (For Reference Only) | |||||||

| # | Raw material | Outer Diameter mm |

Inner Diameter of Roll mm |

Width mm |

Thickness mm |

Weight kgs |

Remarks |

| 1 | Outside Non-Woven Fabrics | Max. 600 (Optimal ≤500) |

D70~D80 | 260~280 | N/A | Max. 50 | 1 Layer |

| 2 | Filtering Cotton | Max. 600 (Optimal ≤500) |

D70~D80 | 260~280 | N/A | Max. 20 | 1~3 Layer |

| 3 | Melt-Blown Fabric | Max. 600 (Optimal ≤500) |

D70~D80 | 260~280 | N/A | Max. 25 | 2 Layers |

| 4 | Inside Non-Woven Fabrics | Max. 600 (Optimal ≤500) |

D70~D80 | 260~280 | N/A | Max. 25 | 1 Layer |

| 5 | Nose Bridge Strip | Max. 350 | 105~200 | 3~5±0.2 | 0.5~1.0±0.1 (Optimal 1mm) |

Max. 20 | 1 Roll, PE (Width ≤100mm) |

| 6 | Earband | Max. 200 | D16~D40 | 3-5 | N/A | Max. 6 | 2 Rolls |

| Commonly Used Brands of Automatic N95 Masks KN95 Masks Making Machine | ||

| No. | Accessories | Brand |

| 1 | PLC | XINJE |

| 2 | Digital Photoelectric Sensor | Justech/OMRON |

| 3 | Touch Screen | XINJE |

| 4 | Motor | XINJE or HCFA |

| 5 | Ultrasonic Welding | CONPROFE |

| 6 | Lead Screw & Slide Rail | HIWIN |

| 7 | Cylinder & Components | AirTAC |

| 8 | Machining Parts & Sheet Metal | Self-Made, Customizable Colors |

| Note: If the accessories are affected by the delivery time, they will be replaced with domestic equivalent brands | ||

| Configuration List of Automatic N95 Masks KN95 Masks Making Machine | |||

| Serial Number | Name | Specifications | Quantity |

| 1 | Ultrasonic | 20K 2600W | 2 Sets |

| 15K 4200W | 1 Set | ||

| 15K 2600W | 1 Set | ||

| 2 | Servo Motor | 400W | 7 pcs |

| 750W | 5 pcs | ||

| 1500W | 1 pcs | ||

| 3 | Die Cutter | Each for Pattern Printing, Sealing, Roller Cutting | 1 Set |

| 4 | Touch Screen | 7" | 1 pcs |

| 5 | PLC | XDH-60T4 | 1 pcs |

| Note: If required for structural adjustment or customization, the configuration list is subject to actual acceptance! | |||

05 3M Automatic Cup Type Masks Making Machine with Sponge Strips 10-15pcs per Minute |

06 3M Automatic Cup Type Masks Making Machine with Sponge Strips 10-15pcs per Minute |

07 3M Automatic Cup Type Masks Making Machine with Sponge Strips 10-15pcs per Minute |

08 3M Automatic Cup Type Masks Making Machine with Sponge Strips 10-15pcs per Minute |

08 3M Automatic Cup Type Masks Making Machine with Sponge Strips 10-15pcs per Minute LWH |

3M Automatic Cup Type Masks Making Machine with Sponge Strips Output: 10-15pcs per Minute Power Supply: 220V, 50/60Hz±10% Power: 16kW Air Supply: 0.6-0.8MPa Machine Sizes: 7,699x2,613x1,726mm Machine Weight: 2,400kgs Logo can be customized, optionally equipped with breathing valve, inkjet printer |

|

The Cup-Shaped Cold Pressing Automatic Masks Making Machine is a production equipment that automatically produces cup-shaped masks. This automatic cup-shaped mask machine can automatically complete the shaping, sealing, cutting, and sticking of the cup-shaped mask with three to five layers of materials. Integrating multi-functions into one machine, the direct product is a single cup mask, high efficiency, special labor saving, stable machine performance, low noise, and continuous work; PLC program control, advanced and intuitive; steel structure, more stable; great performances save labor and improve production efficiency. This fully automatic cup mask machine is suitable for the production of cup masks, gas masks, N95 masks and other masks. |

| Equipment Parameters of 3M Automatic Cup Type Masks Making Machine | ||

| Electrical Components | Controller | XINJE |

| HMI | XINJE 7" Colorful Touch Screen | |

| Sensor | Omron | |

| Ultrasonic Welder | CONPROFE | |

| Pneumatic Components | Clamping Cylinder | AirTAC |

| Solenoid Valve | AirTAC | |

| Oil-Water Separator | China Origin | |

| Mechanical Accessories | Lead Screw & Slide Rail | HIWIN |

| Machining Parts & Whole Machine | Self-Made | |

| Product Specifications | Mask Specifications | Cup Style |

| Earband Length | 260mm, Adjustable | |

| Earband Specifications | 7mm, Customizable | |

| Nose Bridge Specifications | 5*0.5mm | |

| Welding Spots Spacing | 60mm, Adjustable | |

| Welding Spot Size | 6x12mm Straight Lines, Customizable | |

| Welding Time | 2~3 s | |

| Equipment Specifications | Welding Method | Continuous Welding |

| Program Storage | Simple and Adjustable | |

| Operation Safety Protection | Emergency Stop | |

| Operating Height | 1400mm | |

| Operating Environment | Ambient temperature does not exceed 40℃, no flammable nor corrosive gas, no dust (cleanness is not below 100,000 level) |

|

| Air Pipe Specifications | D12mm | |

| Air Supply | 0.6~0.8MPa (Dry Air Source)/20L/min | |

| Power Specifications | AC220V 50/60Hz±10% | |

| Input power | 18kW | |

| Equipment Weight | ~2400 kgs | |

| Overall Dimensions | L8200*W2200*H1900mm | |

| Technical Parameters Table of Materials of 3M Automatic Cup Type Masks | |||||||

| # | Raw Materials | Outer Diameter mm |

Inner Diameter of Roll, mm |

Width mm |

Thickness mm |

Weight kgs |

Remarks |

| 1 | 200g Needle-Punched Cotton | Max. 600 (Optimal ≤500) |

D70~D80 | 260 | NA | Max20 | 1 Layer |

| 2 | 25g Melt-Blown Fabric | Max. 600 (Optimal ≤500) |

D70~D80 | 260 | NA | Max20 | 3 Layers |

| 3 | 50g Non-Woven Fabrics | Max. 600 (Optimal ≤500) |

D70~D80 | 260 | NA | Max. 20 | 1 Layer, According to Needs |

| 4 | Nose Bridge Strip | Max. 350 | 105~200 | 5±0.2 | 0.5~1.0±0.1 (Optimal 1mm) |

Max. 20 | 1 Roll, Aluminum (Width ≤100mm) |

| 5 | Earband | Max. 200 | D16~D40 | 5-7 | NA | Max. 6 | 2 Rolls |

09 Automatic KF94 Fish Shaped Masks Making Machine 10 Servo Bus Systems 100-120 per Minute |

10 Automatic KF94 Fish Shaped Masks Making Machine 10 Servo Bus Systems 100-120 per Minute |

11 Automatic KF94 Fish Shaped Masks Making Machine 10 Servo Bus Systems 100-120 per Minute |

12 Automatic KF94 Fish Shaped Masks Making Machine 10 Servo Bus Systems 100-120 per Minute |

|

Automatic KF94 fish shaped masks making machine is a newly developed mask machine. Automatic KF94 fish shaped masks making machine produces KF94 mask products. The process flow is: 3-5 layers of material roll->loading onto machine->ultrasonic welding peripheral->rolling and cutting->folding->station welding->roll and cut out the body ->automatically turn the piece and convey it to the ear belt machine->welding the left and right ear belts->output of the finished marks. Automatic KF94 fish shaped masks making machine has a high degree of automation, touch screen operation, and language support for Chinese, English, Korean and Japanese. Automatic KF94 fish shaped masks making machine is controlled by PLC programming. It can emboss, fold, perforate, and trim the mask at one time. It has a special manufacturing process, clear lines and no deformation during production, which can greatly reduce material waste and can effectively guarantee the quality of masks. According to the different raw materials used, the masks produced by automatic KF94 fish shaped masks making machine can also meet different standards such as FFP1, FFP2, N95, etc. The earbands are elastic, so that the wearer’s ears are comfortable, and the mask's filtering fabric layer filters well, which is suitable for Asian's face shape, suitable for high pollution industries such as construction and mining. |

| Main Configuration of Automatic KF94 Fish Shaped Masks Making Machine | ||

| Electrical Components | Controller | XINJE |

| HMI | XINJE 7-inch color touch screen | |

| Sensor | OMRON | |

| Earband Rotating Motor | 400W Servo Motor | |

| Ultrasonic Wave | CONPROFE | |

| Servo | XINJE | |

| Pneumatic Components | Clamping cylinder | AirTAC |

| Solenoid valve | AirTAC | |

| Mechanical Accessories | Lead Screw & Slide Rail | HIWN |

| Machining and Sheet Metal | Self-Made | |

| Technical Parameters of Automatic KF94 Fish Shaped Masks Making Machine | ||

| Product Specifications | Mask Specifications | Fish Type Face Masks |

| Earband Length | 160-180mm | |

| Welding Spots Spacing | Adjustable from 30mm to 45mm | |

| Welding Spot Size | 10*10mm, Customized | |

| Welding Time | 100-200ms | |

| Equipment Specifications | Welding Method | Continuous/Instant Welding |

| Program Storage | Simple & Adjustable | |

| Operation Safety Protection | Emergency Stop | |

| Action Protection | Software Action Interlock | |

| Operating Height | 1200mm | |

| Operating Environment | Ambient temperature does not exceed 40℃, no flammable or corrosive gas, no dust (cleanness is not below 100,000 level) | |

| Air Pipe Specifications | D12mm, 2pcs | |

| Air Supply | 0.5~0.7MPa Dry Air, 20L/min | |

| Power Specifications | AC 220V/380V, 50/60Hz±10% | |

| Rated Power | 16kW | |

| Equipment Weight | ~1,200kgs | |

| Overall Dimensions | L5305*W3195*H1700mm | |

Raw Materials Recommendations for KF94 Fish Shaped Masks The existing KF94 mask consists of a total of 4 layers, and the middle 2 layers have MB non-woven filter effect. The recommended width of this device is 240mm, and it can also provide a width of 260mm. Please refer to the raw material recommendation table above. The recommended materials for KF94 masks have a significant impact on the quality. The below table is for reference. |

|||

| From Outside to Inside (240 or 260 Width) | kgs/capacity | ||

| Layer 1st | SS Grade, 50g Non-Woven Fabric | Outwards | 480 pcs |

| Layer 2nd | 99 Grade 25g MB Melt-Blown Fabric | 960 pcs | |

| Layer 3rd | 99 Grade 25g MB Melt-Blown Fabric | 960 pcs | |

| Layer 4th | SS Grade 25g Non-Woven Fabric | Innermost | 960 pcs |

| Earband | 3.00mm Ear Cord, Nylon, Round, Single | 2200 pcs | |

| Nose Bridge | Double Core 0.45*3.0*1.0mm, Wire + PE/PP | 1250 pcs | |

| Configuration List of of Automatic KF94 Fish Shaped Masks Making Machine | |||

| # | Name | Specifications | Quantity |

| 1 | Ultrasonic Welder | 20K 2600W | 3 Sets |

| 15K 2600W | 1 Set | ||

| 2 | Servo Motor | 400W | 5 pcs |

| 750W | 5 pcs | ||

| 3 | Die Cutter | Complete Set (Printing 2, Roll Cutting 2) | 1 Set |

| 4 | Touch Screen | 7" | 1 pcs |

| 5 | PLC | XDH-60T4 | 1 pcs |

| XD3 | 1 pcs | ||

13 Automatic Flat Masks Making Machine 120-150pcs per Minute |

14 Automatic Flat Masks Making Machine 120-150pcs per Minute |

15 Automatic Flat Masks Making Machine 120-150pcs per Minute |

16 Automatic Flat Masks Making Machine 120-150pcs per Minute |

17 Automatic Flat Masks Making Machine 120-150pcs per Minute |

Automatic Flat Masks Making Machine Output: 120-150pcs per Minute Power Supply: 220V, 50/60Hz±5% Power: 10kW Air Supply: 0.5-0.7MPa Machine Sizes: 4,210x2,340x2,000mm Machine Weight: 750kgs 10+ Languages such as Chinese, English, Korean |

Introduction of Automatic One-to-One Flat Masks Making Machine Fully automatic one-to-one flat face masks making machine is developed by high-tech engineers. It has beautiful appearance, stable performance, low failure rate, small size, small area. Its aluminum alloy structure is beautiful and firm, no rust. Fast production speed, stability, high performance and whole configuration. Workers only need to install the production raw materials on the feeding rack. After the debugging, the fully automatic one-to-one flat face masks making machine will automatically produce. Only one person is required to operate the packaging, which fully realizes the full automatic production. The fully automatic one-to-one flat face masks making machine adopts ultrasonic welding method, which is hygienic and environmentally friendly. The fully automatic one-to-one flat face masks making machine can produce all kinds of non-woven masks, smooth cloth masks, gauze masks, activated carbon masks, double nose masks, etc. The fully automatic one-to-one flat face masks making machine can produce 1-4 layers of non-woven masks. The fully automatic one-to-one flat face masks making machine is simple and convenient to operate and adjust, has good stability, accurate counting, and high efficiency, which will help enterprises create greater profits. |

| Main Configuration of Fully Automatic Flat Face Masks Making Machine | ||

| Electrical Components | Controller | XINJE |

| HMI | XINJE 7" Color Touch Screen | |

| Sensor | OMRON | |

| Feeding Motor | TAIKN | |

| Earband Rotating Motor | XINJE | |

| Ultrasonic Welder | NewPower or CONPROFE | |

| Clamping Cylinder | AirTAC | |

| Solenoid Valve | AirTAC | |

| Mechanical Accessories | Slide Rail | HIWIN |

| Machining Parts | Self-Made | |

| Technical Specifications of Fully Automatic Flat Face Masks Making Machine | ||

| Product Specifications | Mask Specifications | 175(±10)*95(±10)mm |

| Earband Length | 160-170mm | |

| Welding Spots Spacing | 80mm-90mm | |

| Welding Spot Size | 10-14MM, Customized | |

| Equipment Specifications | Welding Method | Continuous/Instant Welding |

| Program Storage | Simple and Adjustable | |

| Operation Safety Protection | Emergency Stop | |

| Operating Height | 1200mm | |

| Operating Environment | Ambient temperature does not exceed 40℃, no flammable or corrosive gas, no dust (cleanness is not below 100,000 level) | |

| Air Pipe Specifications | D12mm | |

| Supply Air | 0.5-0.7MPa | |

| Power Specifications | AC 220V/380V, 50/60Hz±10% | |

| Rated Power | 10kW | |

| Equipment weight | ~750kgs | |

| Overall Dimensions | L4210mm*W2340mm*H2000mm | |

| Technical Parameters Table of Flat Masks' Material | |||||||

| No. | Raw Materials | Outer Diameter mm |

Inner Diameter of Roll, mm |

Width mm |

Thickness mm |

Weight kgs |

Remarks |

| 1 | Outside Non-Woven Fabrics | Max. 600 (Optimal ≤500) |

D70~D80 | 200 | N/A | Max. 20 | 1 Layer |

| 2 | Melt-Blown Fabric | Max. 600 (Optimal ≤500) |

D70~D80 | 175 | N/A | Max. 20 | 1~3 Layers |

| 3 | Inside Non-Woven Fabrics | Max. 600 (Optimal ≤500) |

D70~D80 | 175 | N/A | Max. 20 | 1 Layer |

| 4 | Nose Bridge Strip | Max. 350 | 105~200 | 3±0.2 | 0.5~1.0±0.1 (Optimal 1mm) | Max. 20 | 1 Roll, PE (Width ≤ 100mm) |

| 5 | Earband | Max. 200 | D16~D40 | 3 | N/A | Max. 6 | 2 Rolls |

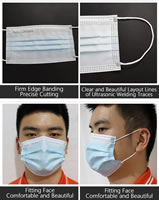

001 N95 Masks KN95 Masks |

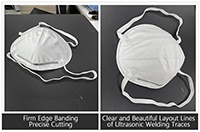

002 Cup Type Masks |

003 KF94 Fish Shaped Masks |

004 Flat Masks |

Masks Firm Edge Banding Precise Cutting Plus Clear and Beautiful Layout Lines of Ultrasonic Welding Traces |

| Copyright © Pimpex@RPM Since 2002 www.plasticimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |