| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

|

|

|

|

Manifesto of our technique team: Manifesto of our manufacturing team: Manifesto of our sales team: |

|

Automatic Two Stations Plastic Injection Blow Moldnig (IBM) Machine

Model WIB40, 1 Row Mold in 1 Station, 2 Rotational Stations

This machine could be widely used to produce pharmaceutical bottles, medicine packaging bottles, health care products bottles, cosmetic cream jars/bottles, mascara eyelash tubes, chemical pesticide bottles, baby feeding bottles, sports water cups, electric water heater kettle, christmas lampballs and stationery containers, etc. |

No |

Item |

Unit |

Data |

No |

Item |

Unit |

Data |

|

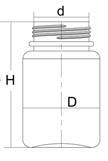

Cavities |

Neck Diameter(d) |

Bottle Diameter(D) |

Bottle Height(H) |

01 |

Screw Diameter | mm |

40 |

08 |

Motor Power | KW |

15 |

mm |

mm |

mm |

||

02 |

Screw Speed | r/min |

0~180 |

09 |

Heater Power | KW |

7 |

2 |

50 |

85 |

180 |

|

03 |

Injection Capacity | g |

150 |

10 |

Compressed Air | MPa |

0.6~1.2 |

4 |

36 |

65 |

120 |

|

04 |

Injection Clamping Force | KN |

200 |

11 |

Cooling Water | bar |

1~3 |

6 |

30 |

55 |

100 |

|

05 |

Blow Clamping Force | KN |

32 |

12 |

Machine Size | cm |

290*140*220 |

8 |

25 |

38 |

90 |

|

06 |

Production Speed | pcs/h |

1100~2000 |

13 |

Machine Weight | Kg |

4500 |

|||||

07 |

Suitable Materials | PE, PP, PS, SAN |

||||||||||

|

Automatic Two Stations Plastic Injection Blow Moldnig (IBM) Machine

Model WIB50, 1 Row Mold in 1 Station, 2 Rotational Stations

This machine could be widely used to produce pharmaceutical bottles, medicine packaging bottles, health care products bottles, cosmetic cream jars/bottles, mascara eyelash tubes, chemical pesticide bottles, baby feeding bottles, sports water cups, electric water heater kettle, christmas lampballs and stationery containers, etc. |

No |

Item |

Unit |

Data |

No |

Item |

Unit |

Data |

|

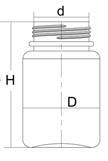

Cavities |

Neck Diameter(d) |

Bottle Diameter(D) |

Bottle Height(H) |

01 |

Screw Diameter | mm |

50 |

08 |

Motor Power | KW |

18.5 |

- |

mm |

mm |

mm |

|

02 |

Screw Speed | r/min |

0~180 |

09 |

Heater Power | KW |

11 |

4 |

48 |

90 |

200 |

|

03 |

Injection Capacity | g |

265 |

10 |

Compressed Air | MPa |

0.6~1.2 |

6 |

39 |

75 |

160 |

|

04 |

Injection Clamping Force | KN |

280 |

11 |

Cooling Water | bar |

1~3 |

8 |

33 |

60 |

120 |

|

05 |

Blow Clamping Force | KN |

65 |

12 |

Machine Size | cm |

330*140*220 |

10 |

27 |

45 |

100 |

|

06 |

Production Speed | pcs/h |

1100~2000 |

13 |

Machine Weight | Kg |

4500 |

|||||

07 |

Suitable Materials | PE, PP, PS, SAN |

||||||||||

Automatic Two Stations Plastic Injection Blow Moldnig (IBM) Machine

Model WIB50D, 2 Rows Mold in 1 Station, 2 Rotational Stations

No |

Item |

Unit |

Data |

No |

Item |

Unit |

Data |

|

Cavities |

Neck Diameter(d) |

Bottle Diameter(D) |

Bottle Height(H) |

01 |

Screw Diameter | mm |

55 |

08 |

Motor Power | KW |

22 |

- |

mm |

mm |

mm |

|

02 |

Screw Speed | r/min |

0~200 |

09 |

Heater Power | KW |

11 |

12 |

30 |

52 |

110 |

|

03 |

Injection Capacity | g |

320 |

10 |

Compressed Air | MPa |

0.6~1.2 |

14 |

25 |

45 |

100 |

|

04 |

Injection Clamping Force | KN |

350 |

11 |

Cooling Water | bar |

1~3 |

16 |

20 |

38 |

90 |

|

05 |

Blow Clamping Force | KN |

65 |

12 |

Machine Size | cm |

340*140*220 |

18 |

16 |

33 |

90 |

|

06 |

Production Speed | pcs/h |

2800~4300 |

13 |

Machine Weight | Kg |

4500 |

|||||

07 |

Suitable Materials | PE, PP, PS, SAN |

||||||||||

No |

Item |

Unit |

Data |

No |

Item |

Unit |

Data |

|

Cavities |

Neck Diameter(d) |

Bottle Diameter(D) |

Bottle Height(H) |

01 |

Screw Diameter | mm |

52 |

08 |

Motor Power | KW |

22 |

- |

mm |

mm |

mm |

|

02 |

Screw Speed | r/min |

0~180 |

09 |

Heater Power | KW |

13 |

1 |

85 |

110 |

230 |

|

03 |

Injection Capacity | g |

320 |

10 |

Compressed Air | MPa |

0.8~1.2 |

2 |

62 |

95 |

200 |

|

04 |

Injection Clamping Force | KN |

350 |

11 |

Cooling Water | bar |

1~3 |

3 |

48 |

85 |

160 |

|

05 |

Blow Clamping Force | KN |

65 |

12 |

Machine Size | cm |

340*140*240 |

4 |

42 |

65 |

160 |

|

06 |

Production Speed | pcs/h |

300~720 |

13 |

Machine Weight | Kg |

5000 |

|||||

07 |

Suitable Materials | PC, PMMA |

||||||||||

Automatic One Station Plastic Injection Blow Moldnig (IBM) Machine

|

||

Technical Parameters of Automatic One Station Plastic Injection Blow Moldnig (IBM) Machine WB07-5T, WB07-5CE |

||||||||||||

No |

Item |

Unit |

Data |

No |

Item |

Unit |

Data |

|

Cavities |

Neck Diameter(d) |

Bottle Diameter(D) |

Bottle Height(H) |

01 |

Screw Diameter | mm |

40 |

08 |

Motor Power | KW |

11 |

- |

mm |

mm |

mm |

|

02 |

Screw Speed | r/min |

0~190 |

09 |

Heater Power | KW |

7 |

2 |

60 |

95 |

180 |

|

03 |

Injection Capacity | g |

175 |

10 |

Compressed Air | MPa |

0.6~1 |

4 |

42 |

75 |

150 |

|

04 |

Injection Clamping Force | KN |

150 |

11 |

Cooling Water | bar |

1~3 |

6 |

36 |

60 |

150 |

|

05 |

Blow Clamping Force | KN |

30 |

12 |

Machine Size | cm |

230*125*250 |

8 |

30 |

45 |

100 |

|

06 |

Production Speed | pcs/h |

~850~1600 |

13 |

Machine Weight | Kg |

2500 |

10 |

12 |

30 |

60 |

|

07 |

Suitable Materials | PE, PP, PS, SAN |

Bottle Volume |

2ml~800ml |

||||||||

|

||||||||||||

Automatic One Station Plastic Injection Blow Moldnig (IBM) Machine

|

||

Technical Parameters of Automatic One Station Plastic Injection Blow Moldnig (IBM) Machine WB2PC-2T, WB2PC-2CE |

||||||||||||

No |

Item |

Unit |

Data |

No |

Item |

Unit |

Data |

|

Cavities |

Neck Diameter(d) |

Bottle Diameter(D) |

Bottle Height(H) |

01 |

Screw Diameter | mm |

52 |

08 |

Motor Power | KW |

18.5 |

- |

mm |

mm |

mm |

|

02 |

Screw Speed | r/min |

0~180 |

09 |

Heater Power | KW |

13 |

1 |

85 |

115 |

230 |

|

03 |

Injection Capacity | g |

320 |

10 |

Compressed Air | MPa |

0.8~1.2 |

2 |

62 |

100 |

220 |

|

04 |

Injection Clamping Force | KN |

310 |

11 |

Cooling Water | bar |

1~3 |

3 |

48 |

85 |

180 |

|

05 |

Blow Clamping Force | KN |

65 |

12 |

Machine Size | cm |

285*150*260 |

4 |

42 |

65 |

160 |

|

06 |

Production Speed | pcs/h |

140~400 |

13 |

Machine Weight | Kg |

4000 |

|||||

07 |

Suitable Materials | PC, PMMA, PETG (PE, PP, PS, SAN) |

Bottle Volume |

~2000ml

|

||||||||

|

||||||||||||

Common IBM Mould

|

Special Transparent IBM Mould

|

Technical Features of Our Automatic Plastic Injection Blow Moldnig (IBM) Machinery

|

Minimum 2ml bottle, Maximum 2000ml bottle Customerized bigger bottles are available if Buyers would afford more investments. |

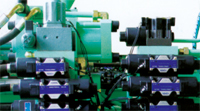

| The specialty comes from meticulosity attitude. All key parts of our IBM machine adopts top-grade imported components to fully guarantee whole machine's high performance and long term high effective running. It reflects our advanced market awareness and strategic foresight. Please refer to IBM Machines' Components List | |||

IBM Machine Hydraulic Components |

IBM Machine Electric Components |

IBM Machine Pneumatic Components |

|

| Behind those well-known brands like P&G, Avon, Amway, WalMart, Starbucks Coffee, Evenflo, Rubbermaid, Cool Gear, DrBrowns, Babisil, there are our supports! Our automatic plastic injection blow molding (IBM) machines are adopted in many fields like pharmaceutical/medicine bottles, cosmetics jars/bottles, daily chemcials containers, baby bottles, sport cups ect. You will be impressed & satisfied to work with us for your projects. |

| Copyright © Pimpex@RPM Since 2002 www.plasticimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |