| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

|

|

Blisters Packaging Machinery Set

Pimpex supplies blisters packaging machinery set, blisters packing machines, hard blisters packing machines, soft blisters packing machines, automatic needle loaders, automatic syringes loaders, etc.

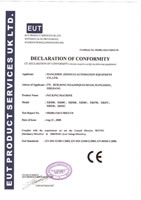

Established in 2002, a high-tech enterprise provides innovative packaging and processing technologies for the medical and food industries. The engineering specialist develops, manufactures and markets system solutions for a wide range of industrial applications: disposable medical instrument, medical dressing as well as processing equipment for automatic feeding and loading. The company operates from two locations in Hangzhou and Deqing, is divided into two business areas for designing and manufacturing. Deqing production base covers 13 acre with 4800 sqm standard facility and around 60 staff. It has established a complete quality assurance system. We are both ISO 9001:2008 and CE certified. OUR AIM

OUR PROMISES:

|

Video of Multi-Functions Blisters Packing Machine, XB-40C |

0100 Blisters Packaging Machinery - |

0200 Blisters Packaging Machinery Blisters |

0301 Declaration of Conformity - |

0302 ISO 9001 Certificate - |

Go Back Various Pricings for Plastics Related Projects Center

| Copyright © Pimpex@RPM Since 2002 www.plasticimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |