| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

|

|

Technical Data of Automatic Injection Blow Molding Plastic Machines

|

1 |

Model of Machinery |

. |

(Injection Blow Molding Machine) WB07-5 |

(Injection Blow Molding Machine) WB2-1B |

|||||||||

|

2 |

Screw Diameter |

mm |

40 |

50 |

|||||||||

|

3 |

Screw Speed |

r/min |

0-190 |

0-180 |

|||||||||

|

4 |

Injection Capacity |

g |

175 |

300 |

|||||||||

|

5 |

Injection Clamping Force |

KN |

150 |

210 |

|||||||||

|

6 |

Blow Clamping Force |

KN |

30 |

65 |

|||||||||

|

7 |

Suitable Material |

. |

PE, PP, PS, SAN

|

||||||||||

|

8 |

Production Speed |

pcs/h |

850-1600 |

1100-2000 |

|||||||||

|

9 |

Motor Power |

KW |

11 |

15 |

|||||||||

|

10 |

Heater Capacity |

KW |

7 |

11 |

|||||||||

|

11 |

Compressed Air |

MPa |

0.6-1.2 |

0.6-1.2 |

|||||||||

|

12 |

Cooling Water |

bar |

1-3 |

1-3 |

|||||||||

|

13 |

Dimension of Machine |

cm |

230×125×250 |

280×140×260 |

|||||||||

|

14 |

Machine Weight |

kg |

2500 |

3500 |

|||||||||

|

15 |

Dimensions |

Mould Cavities |

. |

2 |

4 |

6 |

8 |

9 |

4 |

6 |

9 |

10 |

12 |

|

Bottle Mouth (d) |

mm |

60 |

42 |

36 |

30 |

20 |

50 |

42 |

36 |

30 |

18 |

||

|

Bottle Body (D) |

mm |

100 |

80 |

60 |

50 |

42 |

110 |

80 |

55 |

50 |

40 |

||

|

Bottle Height (H) |

mm |

200 |

180 |

150 |

150 |

80 |

220 |

200 |

180 |

150 |

80 |

||

1 |

Model of Machine |

- |

(Injection Blow Molding Machine for PC) |

(Injection Blow Molding Machine for PC) WB2PC-2 |

|||||||||

2 |

Screw Diameter |

mm |

42 |

52 |

|||||||||

3 |

Screw Speed |

r/min |

0-180 |

0-180 |

|||||||||

4 |

Injection Capacity |

g |

190 |

320 |

|||||||||

5 |

Injection Clamping Force |

KN |

170 |

320 |

|||||||||

6 |

Blow Clamping Force |

KN |

50 |

65 |

|||||||||

| 7 | Suitable Materials |

- |

PMMA, PC (PE, PP, PS, SAN) |

||||||||||

8 |

Production Speed |

pcs/h |

200-720 |

150-400 |

|||||||||

9 |

Motor Power |

KW |

15 |

18.5 |

|||||||||

10 |

Heater Capacity |

KW |

11 |

13 |

|||||||||

11 |

Compressed Air |

MPa |

0.8-1.2 |

0.8-1.2 |

|||||||||

12 |

Cooling Water |

bar |

1-3 |

1-3 |

|||||||||

13 |

Dimension of Machine |

cm |

260×134×260 |

285x150x260 |

|||||||||

14 |

Machine Weight |

kg |

3000 |

4000 |

|||||||||

15 |

Bottle Dimensions |

Mould Cavities |

- |

1 |

2 |

3 |

4 |

5 |

1 |

2 |

3 |

4 |

5 |

Bottle Mouth |

mm |

75 |

54 |

44 |

38 |

32 |

75 |

54 |

44 |

38 |

32 |

||

Bottle Body |

mm |

100 |

90 |

80 |

65 |

55 |

100 |

90 |

80 |

65 |

55 |

||

Bottle Height |

mm |

200 |

180 |

180 |

160 |

120 |

200 |

180 |

180 |

160 |

120 |

||

| Injection Blow Molding Machine Main Specification |

|

High Speed Automatic Injection Blow Molding Machine |

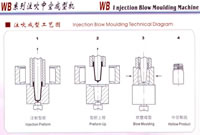

Injection Blow Molding Technical Diagram |

Container Volume 2ml 5000ml 30000ml from Injection Blow Molding Machine |

Very Suitable for PC Bottles from Injection Blow Molding Machine |

|

Mailing Address:

Flat B601, No.29, XingHua Road, SiMing District, XiaMen City, FuJian Province, P.R.C. PostCode: 361001 Fax: 0086-0592-5718012 |

| Copyright © Pimpex@RPM Since 2002 www.plasticimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |