Pimpex@RPM supplies hard disks shredders, hard disk bending and punching machines, chip cards crushers, chip mills, cards breakers and plastics/rubber/elastomer crushers, electronics shredders, such as slow speed crushers, medium speed crushers, plastics centralized shredders, rubber/elastomer crushers/pulverizers/micronizers/disintegrators, plus automatic rubber cutting machine, rubber cutting and crushing production line, film sheet crushers/pulverizers/micronizers/disintegrators, double shaft shredders, single shaft shredders, and others auxiliary equiments like water cooled chillers, air cooled chillers, water cooled screw chillers, Industrial air coolers, mold temperature controller, dehumidification dryer, dehumidification and drying system, hopper dryers, europeanization hoppers, box dryers, suction machines, storage barrels, masterbatch machines, ribbon shredders, material sorting equipments, vertical mixers, drum type mixers, horizontal mixers, vibration screening machines, metal separators, etc.

|

01 Office of

Plastic Rubber Elastomer Crushers

Electronics Shredders |

02 Factory of

Plastic Rubber Elastomer Crushers

Electronics Shredders |

The manufacturer was established in 2006 and the production plant is located in Dongguan City, Guangdong Province. Its business philosophy is to create value for customers, create opportunities for employees, and create profits for shareholders. It integrates R&D, production, sales, and service. With its own intellectual property rights and advanced technology, the manufacturer has now become a modern enterprise focusing on "crushing and recycling" and "industrial temperature control."

What it does: The equipments produced and sold by the manufacturer are mainly divided into five series: confidential destruction series, rubber/plastic crushing series, industrial temperature control series, dehumidification and dry noise series, material sorting series. According to customer requirements, it can design and customize personalized fully automatic production lines to realize unmanned, intelligent, personalized and efficient production workshops.

How it does: The manufacturer has an independent research and development center and complete production, processing and testing equipments. Its equipments are 100% qualified before leaving the factory, and the quality of components and finished equipments is better controlled. Every machine it produces has a test report and an e-identity file that can be called at any time.

What makes it different: On the basis of commonly used plastic crushers, our factory has developed a variety of crushing equipments suitable for special materials, so that special materials such as silica gel, elastomer, rubber, MIM, carbon fiber, etc. can be recycled and reused efficiently. At the same time, based on the single-machine operation of the crushing equipments, our factory has developed a variety of new models such as material sorting, specific gravity separation, and confidential destruction. Industrial temperature control is another product line of our factory. We are committed to independent research and development of precise temperature control, and cooperate with many large domestic enterprises to develop temperature control equipment for specific industries, such as: temperature control system for 50-80 meters ultra-large wind power molds, for bag printing's cooling system, etc., have helped partners effectively improve product quality and increase production efficiency.

|

64 Hard Disk Shredder

to Crush Steel Plate, Plastics, Rubber

Wood, Metals, Film, Paper

- |

65 Hard Disk Shredder

to Crush Steel Plate, Plastics, Rubber

Wood, Metals, Film, Paper

Easy Operation, High Security |

66 Hard Disk Shredder

to Crush Hard Disks Mobilephones

USB Disks

U Disks |

66 Hard Disk Shredder

to Crush Steel Plate

Plastics, Rubber, Wood, Metals

Film, Paper, Powerful Multiple Usages |

67 Hard Disk

Bending and Punching Machine

-

- |

68 Hard Disk

Bending and Punching Machine

-

- |

69 Hard Disk

Bending and Punching Machine

Optional Device

Hydraulic Lifting Table |

70 Hard Disk

Bending and Punching Machine

Optional Device

Punching Mould for Solid State Drive |

71 Hard Disk

Bending and Punching Machine

Optional Device Punching Hammer

for Mechanical Hard Disk |

72 Cards Breaker

Smart Cards with Chips

ID Cards, Bank Cards, Credit Cards

Memory Cards, Recharge Cards, Gas Cards

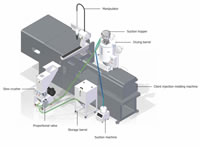

IC Boards, PCB Boards Discs |

73 Cards Breaker

Chips Crushing

-

-

- |

74 Cards Breaker

Bank Cards Crushing

-

-

- |

75 Cards Breaker

Paper Crushing

Statements, Envelopes, Cardboards |

76 Cards Breaker

Anti Counterfeit

Security Labels Crushing |

77 Cards Breaker

Credential Cards Crushing Shredding |

|

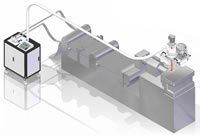

10 Slow Speed Crusher

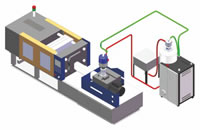

around Injection Molding Machine |

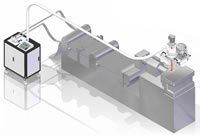

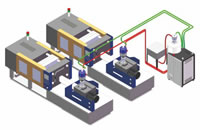

11 Slow Speed Crusher

around Injection Molding Machine

Solution 1 |

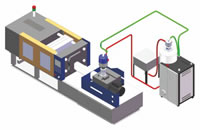

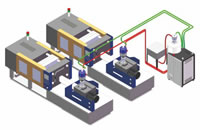

12 Slow Speed Crusher

around Injection Molding Machine

Solution 2 |

13 Slow Speed Crusher

around Injection Molding Machine

Tooth Knife, Hook Knife, Integrated Structure

Movable Knife Cover |

Features of Slow Speed Shredder:

- The inlet hopper and the receiving box are made of stainless steel, which does not pollute the raw materials

- The crushing chamber is plated with hard chrome, the surface is smooth, wear-resistant and easy to clean

- Driven by decelerating motor, low power, slow speed, large torque, low noise and long service life

- No screen design, evenly crushed particles, less dust

- Open crushing chamber, easy disassembly and assembly, convenient and quick cleaning

- Protection function: motor overload protection, limit switch protection

- A 30-second immediate recovery device can be installed to realize the immediate recovery of materials

Tooth knife and hook knife are integrated structure, coarse crushing and fine crushing are carried out at the same time, and the movable knife cover can be taken out for cleaning.

| Model |

SMD-20L |

SMD-30L |

SMD-50L |

SMD-50XL |

| Power |

hp |

2 |

3 |

5.5 |

5.5 |

| kW |

1.5 |

2.2 |

4 |

4 |

| Grinding Chamber |

mm |

255*230 |

260*255 |

345*310 |

350*420 |

| Blades |

Fixed Knife |

2 |

2 |

2 |

8 |

| Hook Knife |

2 |

2 |

3 |

3 |

| Hob |

3 |

3 |

4 |

4 |

| Rotating Speed |

rpm |

20-28 |

20-28 |

20-28 |

20-28 |

| Crushing Capacity |

kgs/hr |

5-10 |

8-15 |

10-20 |

10-20 |

| Dimension |

cm |

54*40*90 |

54*40*90 |

61*50*127 |

120*56*130 |

| Weight |

kgs |

245 |

290 |

350 |

360 |

|

|

27 Rubber Elastomer Crusher

Pulverizer, Micronizer, Disintegrator |

28 Rubber Elastomer Crusher

Pulverizer, Micronizer, Disintegrator

Crushed Rubber, Crushed Elastomer |

29 Rubber Elastomer Crusher

Pulverizer, Micronizer, Disintegrator

Crushed Rubber, Crushed Elastomer |

Rubber/Elastomer Crusher:

This series of pulverizers are specially designed for soft and viscous materials. The specially designed cutting angle and speed of the cutter are matched with high cutting performance cutters to crush the soft rubber materials that are prone to sticking to the cutter, clumping, and clogging the filter. For example: rubber, silica gel, elastomer, etc., the minimum can be crushed to less than 2mrn. This series is also suitable for crushing engineering plastics, especially for reinforced materials, such as engineering plastics added with glass fiber and carbon fiber, its wear resistance is more excellent.

Features of Rubber/Elastomer Crusher:

- The whole series is equipped with circulating water cooling to reduce the working temperature of the machine;

- Optional powder adder can be used to accurately add the amount of blocking agent during crushing;

- Optional low-temperature crusher, for temperature-sensitive materials, control the temperature of the material to avoid stickiness;

- Optional wear-resistant grinder, the crushing cavity adopts wear-resistant material with heat treatment to increase wear resistance;

- Optional rubber cutting machine, combined into a cutting-conveying-crushing automatic production line, improve work efficiency.

| Model |

SMD-300V |

SMD-400V |

SMD-500V |

SMD-750V |

SMD-1000V |

| Power |

hp |

30 |

40 |

50 |

75 |

100 |

| kW |

22 |

30 |

37 |

55 |

75 |

| Grinding Chamber |

mm |

570*400 |

530*500 |

785*500 |

960*630 |

1130*630 |

| Blades |

Fixed Knife |

2 |

4 |

4 |

4 |

4 |

| Moving Knife |

8 |

6 |

8 |

8 |

8 |

| Crushing Capacity |

kgs/hr |

400-800 |

400-800 |

700-1200 |

1000-1500 |

1500-2000 |

| Dimension |

cm |

150*116*173 |

181*121*210 |

180*147*212 |

190*175*242 |

200*192*242 |

| Weight |

kgs |

1500 |

2000 |

2500 |

3900 |

4500 |

|

36 Traction Type Film Sheet Crusher

Pulverizer, Micronizer, Disintegrator

after Film Blowing Machine

Slitting Machine, Extruder |

37 Traction Type Film Sheet Crusher

Pulverizer, Micronizer, Disintegrator

after Film Blowing Machine,

Slitting Machine, Extruder |

38 Distributor of

Traction Type Film Sheet Crusher

Pulverizer, Micronizer, Disintegrator

after Film Blowing Machine,

Slitting Machine, Extruder |

40 Traction Type Film Sheet Crusher

Pulverizer, Micronizer, Disintegrator

after Film Blowing Machine

Slitting Machine, Extruder, Solution 1 |

41 Traction Type Film Sheet Crusher

Pulverizer, Micronizer, Disintegrator

after Film Blowing Machine

Slitting Machine, Extruder, Solution 2 |

39 Distributor of

Traction Type Film Sheet Crusher

Pulverizer,

Micronizer, Disintegrator

after Film Blowing Machine

Slitting Machine, Extruder |

Traction Type Film Sheet Crusher

This series of crushers are mainly used for online crushing and recycling of films and sheets. It can be applied to extruders, slitters, film blowing machines, and the end of extruders. The traction device on the crusher will cut the cut corners. The material is automatically pulled into the pulverizer for crushing, and then the crushed material is sent to the main equipment for recycling by the air conveying device and screw, so that the side material is automatically crushed and recycled, with high efficiency, low energy consumption, and saving labor costs.

- SMD Series: suitable for online crushing of relatively narrow, 2 or more side materials, and the crushed materials can be sent back to the host immediately for use

- SAR Series: suitable for thermoforming, cup making, environmentally friendly lunch box, blister packaging and other forming machine tails, used for online crushing and conveying of net-like residual materials

| Model |

SMD-180/2 |

SMD-290/2 |

SMD-400/2 |

SAR-550 |

SAR-650 |

SAR-800 |

SAR-1000 |

| Traction System |

Traction Motor |

kW |

0.75 |

0.75 |

0.75 |

0.75 |

0.75 |

0.75 |

0.75 |

| Max. Feeding Width |

mm |

150 |

260 |

350 |

500 |

630 |

750 |

980 |

| Traction Thickness |

mm |

0.01-3 |

0.01-3 |

0.01-3 |

0.1-3 |

0.1-3 |

0.1-3 |

0.1-3 |

| Max. Traction Speed |

m/min |

150 |

250 |

250 |

50 |

50 |

50 |

50 |

| Crushing System |

Smashing Motor |

kW |

2.2 |

4 |

5.5 |

7.5 |

7.5 |

11 |

15 |

| Smash Caliber |

mm |

180*160 |

290*220 |

400*250 |

515*250 |

650*250 |

785*250 |

1000*330 |

| Fixed Knives |

pcs |

2 |

2 |

2 |

2 |

2 |

4 |

4 |

| Moving Knives |

pcs |

3 |

6 |

6 |

6 |

6 |

9 |

9 |

| Screen Aperture |

mm |

8 |

8 |

10 |

8 |

8 |

8 |

10 |

| Feeding System |

Feed Fan |

kW |

1.5 |

1.5 |

1.5 |

2.2 |

2.2 |

3.75 |

4 |

| Diameter of Discharge Pipe |

mm |

76 |

76 |

76 |

100 |

100 |

150 |

150 |

| Escort Motor |

kW |

0.75 |

0.75 |

0.75 |

- |

- |

- |

- |

| Escort Method |

|

Screw Feeding |

No Escort |

| Machine Sizes |

|

cm |

98*68*116 |

109*83*118 |

139*95*146 |

140*122*205 |

150*139*205 |

160*134*175 |

181*200*214 |

| Machine Weight |

|

kgs |

510 |

676 |

800 |

1550 |

1750 |

2800 |

5000 |

|

42 Double Shaft Shredder

to Crush Plastics, Rubber, Fiber, Paper

Large Hollow Materials

Various Mixed Waste Materials |

Double Shaft Shredder

The double-shaft shredder is used to crush: plastic, rubber, fiber, paper, wood, large hollow materials, various mixed waste materials, especially waste materials containing metals, or pre-shredded waste materials containing mud, sand and other scraps those are easy to wear tools.

| Model |

SH-500 |

SH-630 |

SH-800 |

SH-1000 |

SH-1200 |

| Motor Power |

hp |

5.5 |

10+10 |

20+20 |

25+25 |

30+30 |

| kW |

4 |

7.5+7.5 |

15+15 |

18.5+18.5 |

22+22 |

| Crushing Cavity Caliber |

cm |

50*41 |

62*56 |

85*56 |

100*63 |

120*75 |

| Rotation Diameter |

mm |

180 |

300 |

240 |

300 |

420 |

| Rotating Speed |

rpm |

18-45 |

18-45 |

18-45 |

18-45 |

18-45 |

| Spindle Size |

mm |

65 |

120 |

90 |

110 |

150 |

| Tool Thickness |

mm |

20-35 |

20-40 |

20-50 |

25-50 |

30-60 |

| Machine Size |

cm |

160*97*135 |

210*90*180 |

240*100*180 |

240*110*140 |

260*130*260 |

| Machine Weight |

kgs |

1200 |

1900 |

2450 |

3000 |

4000 |

|

43 Single Shaft Shredder

to Crush Tough or Medium Hard Materials

Films, Plastics, Bottles

Thick Walled Pipes, Pallets, Turnover Boxes |

Single Shaft Shredder

The single-shaft shredder is suitable for crushing the tough or medium-hard materials that are packed into bundles, such as films, plastic bottles, etc., large-size or high-hardness materials (thick-walled tubes, pallets, turnover boxes, etc.)

| Model |

SB-600 |

SB-800 |

SB-1000 |

SB-1200 |

SB-1500 |

| Motor Power |

hp |

30 |

50 |

75 |

100 |

120 |

| kW |

22 |

37 |

55 |

75 |

90 |

| Feed Inlet Sizes |

mm |

630*985 |

830*1240 |

1030*1440 |

1230*1700 |

1530*1800 |

| Rotation Diameter |

mm |

350 |

400 |

450 |

450 |

500 |

| Rotating Speed |

rpm |

78 |

78 |

78 |

78 |

78 |

| Fixed Knives |

pcs |

2 |

2 |

3 |

4 |

4 |

| Moving Knives |

pcs |

39 |

51 |

63 |

81 |

99 |

| Screen Aperture |

mm |

30-100 |

30-100 |

30-100 |

30-100 |

30-100 |

| Hydraulic Power |

kW |

2 |

3 |

4 |

4 |

5 |

| Machine Size |

cm |

2*1.4*2.1 |

2.4*1.7*1.5 |

2.9*2.2*2.6 |

3.35*2.3*2.65 |

3.5*2.9*2.7 |

| Machine Weight |

kgs |

1200 |

1900 |

2450 |

3000 |

|

|

46 Water Cooled Screw Chiller |

Features of Water Cooled Screw Chiller:

- Using high-efficiency imported brand semi-hermetic screw compressor, reliable operation, high efficiency and easy maintenance.

- The compressor capacity is controlled accurately, and the application range is wide. The system adopts the latest asymmetric rotor tooth profile, and the built-in differential pressure oil lubrication system has low vibration, low noise and high sealing.

- It adopts full touch screen man-machine interface to realize fully automatic control and accurately monitor the unit running in the best condition.

- The unit is waterproof, pressure-proof, anti-corrosion, long life, graded or stepless energy control, to ensure that the unit exerts the maximum energy-saving effect under any load.

- The unit has high operating efficiency, the heat exchanger adopts high-speed heat transfer copper tubes, and the high-efficiency compressor is equipped with a high-efficiency expansion throttling device, which ensures the stable, lasting and efficient operation of the unit.

- The chiller has reliable protection devices: compressor anti-frequent start-up, overcurrent electromechanical protection, compressor motor overheating protection, anti-freezing protection, sight glass, oil heating protection, compressor phase protection, high/low pressure protection, Exhaust high temperature protection, safety valve, easily soluble plug, cut-off protection, etc.

- Unit design: Fully intelligent control, 24 hours non-stop operation.

- Application fields: central air-conditioning, building HVAC, chemical industry, electroplating and oxidation, precision equipment, printing, papermaking, hardware, casting, plastic injection molding industry, food cleaning and freezing. Pharmaceutical industry, electronic circuit board, drum sandwich cooling, space purification treatment, bath cooling, welding and cutting, surface treatment, aluminum profile, glass craft, rubber tire processing, breeding industry, etc.

- The air-cooled type adopts a low-speed radiator fan, and the heat is discharged smoothly, thereby minimizing the noise, the unit vibration is small, and the installation is simple. It is suitable for areas with relatively lack of water sources and does not need to install a water tower.

|

| Model |

SC-100

WSA/B |

SC-180

WSA/B |

SC-230

WSA/B |

SC-300

WSA/B |

SC-370

WSA/B |

SC-470

WSA/B |

SC-620

WSA/B |

SC-790

WSA/B |

SC-930

WSA/B |

Cooling Capacity |

1000kcal |

120.4 |

154.8 |

197.8 |

258 |

318.2 |

404.2 |

533.2 |

679.4 |

799.8 |

| kW/h |

140 |

180 |

230 |

300 |

370 |

470 |

620 |

790 |

930 |

| Power Supply |

|

3N-380V/415V 50Hz/60Hz |

| Temperature Range |

|

5℃-Room Temperature (below 0℃ can be customized) |

| Compressor |

Power |

kW |

30 |

36 |

51 |

51 |

80 |

102 |

130 |

167 |

200 |

| Current |

A |

51 |

65 |

86 |

106 |

135 |

172 |

218 |

280 |

335 |

| Condenser |

Energy Regulation |

|

0%-33%-86%-100% |

0%-25%-50%-75%-100% |

| Form |

|

Semi-Closed Screw Type |

| Evaporator |

Form |

|

Shell and Tube |

| Pipe Diameter |

inch |

3 |

3 |

3 |

3 |

4 |

4 |

5 |

6 |

6 |

| Circulating Pump |

Form |

|

Shell and Tube |

| Pipe Diameter |

inch |

3 |

3 |

3 |

3 |

4 |

4 |

5 |

6 |

6 |

| Machine Sizes |

L |

mm |

2200 |

2359 |

2450 |

2900 |

2900 |

3000 |

3600 |

3600 |

3650 |

| W |

mm |

800 |

800 |

900 |

900 |

900 |

1500 |

1500 |

1500 |

1600 |

| H |

mm |

1500 |

1650 |

1750 |

1800 |

1850 |

1500 |

1650 |

1700 |

1700 |

| Machine Weight |

|

kgs |

960 |

1260 |

1450 |

1710 |

1940 |

2400 |

3050 |

3360 |

3780 |

| Running Weight |

|

kgs |

1280 |

1600 |

1950 |

2300 |

2550 |

3050 |

3800 |

4200 |

3700 |

|

48 Mold Temperature Controller

Water Carrying |

Features of Mold Temperature Controller (Water Carrying):

The water-carrying mold temperature machine uses water as the medium, has good thermal conductivity, rapid heating, low operating cost, convenient use, and reduced energy consumption.

- Small and compact design, convenient and quick installation and positioning

- Perfect safety protection and fault indication

- High-quality pump, stable operation, low noise

- Stainless steel is formed in one piece, with small tube loss and uniform heating

- Unique heating design, suitable for different temperature control places, with obvious energy saving effect

- Microcomputer dual-group PID control, automatic calculation, power saving more than 30%

- Automatic exhaust function at startup

- Detection and display of mold return water temperature

| Model |

SMC-60W |

SMC-90W |

SMC-120W |

SMC-180W |

SMC-60WD |

SMC-90WD |

SMC-120WD |

SMC-180WD |

| Temperature Range |

℃ |

Inlet Water Temperature

+35℃-120℃ (Single System)

|

Inlet Water Temperature

+35℃-120℃ (Dual System) |

| Temperature Control Accuracy |

℃ |

±1℃ |

±1℃ |

| Electric Heating Power |

kW |

6 |

9 |

12 |

18 |

6+6 |

9+9 |

12+12 |

18+18 |

| Pump Power |

hp |

0.5 |

1 |

1 |

2 |

0.5+0.5 |

1+1 |

1+1 |

2+2 |

| Max. Pump Flow |

L/m |

45 |

130 |

130 |

160 |

45+45 |

130+130 |

130+130 |

160+160 |

| Loop Connection Pipeline |

Inch |

3/8"*2 |

3/8"*4 |

3/8"*4 |

3/8"*4 |

3/8"*4 |

3/8"*8 |

3/8"*8 |

3/8"*8 |

| Cooling Water Pipe |

Inch |

1/2" |

1/2" |

| Cooling Method |

|

Direct Cooling |

Direct Cooling |

| Heat Transfer Media |

|

Water |

Water |

| Alarm Function |

|

Lack of Phase/Water Shortage/Over Temperature/Overload |

| Machine Size |

cm |

80*35*60 |

80*35*60 |

80*35*60 |

80*41*66 |

90*45*66 |

90*45*66 |

90*45*66 |

90*50*66 |

| Weight |

kgs |

65 |

68 |

73 |

85 |

120 |

126 |

140 |

160 |

|

49 Mold Temperature Controller

Oil Conveying |

Features of Mold Temperature Controller (Oil Carrying):

The oil transport type mold temperature machine uses heat transfer oil as the medium, which has good thermal stability and high oil temperature, but compared with the water transport type, the operating cost is high, and there is oil pollution.

- Small and compact design, convenient and quick installation and positioning

- Perfect safety protection and fault indication

- High-quality pump, stable operation, low noise

- Stainless steel is formed in one piece, with small tube loss and uniform heating

- Unique heating design, suitable for different temperature control places, with obvious energy saving effect

- Microcomputer dual-group PID control, automatic calculation, power saving more than 30%

- Automatic exhaust function at startup

- Detection and display of mold return water temperature

| Model |

SMC-60 |

SMC-90 |

SMC-120 |

SMC-180 |

SMC-60D |

SMC-90D |

SMC-120D |

SMC-180D |

| Temperature Range |

℃ |

Inlet Water Temperature

+45℃-200℃ (Single System)

|

Inlet Water Temperature

+45℃-200℃ (Dual System) |

| Temperature Control Accuracy |

℃ |

±1℃ |

±1℃ |

| Electric Heating Power |

kW |

6 |

9 |

12 |

18 |

6+6 |

9+9 |

12+12 |

18+18 |

| Pump Power |

hp |

0.5 |

1 |

1 |

2 |

0.5+0.5 |

1+1 |

1+1 |

2+2 |

| Max. Pump Flow |

L/m |

45 |

130 |

130 |

160 |

45+45 |

130+130 |

130+130 |

160+160 |

| Loop Connection Pipeline |

Inch |

3/8"*2 |

3/8"*4 |

3/8"*4 |

3/8"*4 |

3/8"*4 |

3/8"*8 |

3/8"*8 |

3/8"*8 |

| Cooling Water Pipe |

Inch |

1/2" |

1/2" |

| Cooling Method |

|

Direct Cooling |

Direct Cooling |

| Heat Transfer Media |

|

Oil |

Oil |

| Alarm Function |

|

Phase Loss/Oil Shortage/Over Temperature/Overload |

| Machine Size |

cm |

80*35*60 |

80*35*60 |

80*35*60 |

80*41*66 |

90*45*66 |

90*45*66 |

90*45*66 |

90*50*66 |

| Weight |

kgs |

65 |

68 |

73 |

85 |

120 |

126 |

140 |

160 |

|

52 Dehumidification Dryer |

Features of Dehumidification Dryer:

- This series of ceramic honeycomb rotary dehumidifiers are mainly used for large and medium-sized injection molding in factories, and engineering plastics with strong hygroscopicity in extrusion molding equipment are used for high-efficiency dehumidification operations.

- The dew point of the honeycomb runner used by our company can reach below -40℃ under ideal conditions, and the whole system adopts P.I.D.

- The temperature control system is standard equipment, and a dew point meter that can monitor the dehumidification effect of the machine in real time is provided as an option. The maximum drying air volume can reach 4000m3/hr

| Model |

Regenerative Electric Heating Power |

Regenerative Fan Power |

Drying Fan Power |

Dry Air Volume |

Inlet and Outlet Pipe Diameter |

Machine Sizes |

Weight |

| kW |

kW |

kW |

m3/hr |

inch |

mm |

kgs |

| SRD-50 |

3 |

0.2 |

0.4

|

50 |

2" |

1260*480*755 |

145 |

| SRD-80 |

3 |

0.2 |

0.75 |

80 |

2" |

1360*530*820 |

170 |

| SRD-120 |

3 |

0.2 |

0.75 |

120 |

2" |

1360*530*820 |

170 |

| SRD-150 |

4 |

0.4 |

1.5 |

150 |

2.5" |

1560*660*1050 |

260 |

| SRD-200 |

4 |

0.4 |

1.5 |

200 |

2.5" |

1560*660"1050 |

265 |

| SRD-300 |

7.2 |

0.75 |

2.4 |

300 |

3" |

1745*700*1255 |

320 |

| SRD-400 |

7.2 |

0.75 |

3.75 |

400 |

3" |

1745*700*1255 |

320 |

| SRD-500 |

10 |

1.5 |

5.5 |

500 |

4" |

1935*900*1380 |

470 |

| SRD-700 |

10 |

1.5 |

5.5 |

700 |

4" |

1935*900*1380 |

470 |

| SRD-1000 |

15 |

2.4 |

9 |

1000 |

5" |

2145*1300*1550 |

700 |

| SRD-1500 |

20 |

3.75 |

9*2 |

1500 |

6" |

2145*1300*1710 |

1010 |

| SRD-2000 |

20 |

5.5 |

13*2 |

2000 |

8" |

2060*1410*2150 |

1300 |

| SRD-3000 |

30 |

7.5 |

13*3 |

3000 |

8" |

2060*1600*2160 |

1600 |

| SRD-4000 |

40 |

5.5*2 |

13*4 |

4000 |

12" |

2060*2750*2250 |

2200 |

|

| |

53 Three in One Trinity

Dehumidification and Drying System |

54 Dehumidification Dryer Solution 1 |

55 Dehumidification Dryer Solution 2 |

55 Other Auxiliary Series

Hopper Dryer |

56 Other Auxiliary Series

Europeanization Hopper |

57 Other Auxiliary Series

Box Dryer |

58 Other Auxiliary Series

Model 300 Suction Machine |

59 Other Auxiliary Series

Model 700 Suction Machine |

60 Other Auxiliary Series

Model 800 Suction Machine |

61 Other Auxiliary Series

Model 900 Suction Machine |

62 Other Auxiliary Series

Storage Barrel |

63 Other Auxiliary Series

Masterbatch Machine |

|

|

78 Ribbon Shredder

for Printer Ribbon, Film, Coated Ribbon

Hot Color Ribbon, Label, Paper |

79 External Collector of

Ribbon Shredder for

Printer Ribbon, Film, Coated Ribbon

Hot Color Ribbon, Label, Paper |

|

80 Crushed Printer Ribbon, Film, Coated Ribbon

Hot Color Ribbon, Label, Paper

by Ribbon Shredder |

81 Chip Mill for

Crushing, Grinding, Destroying

Plastic, Chips, Silicon Elements

Electronic, Confidential Media Materials |

82 Crush, Grind, Destroy

Plastic, Chips, Silicon Elements

Electronic, Confidential Media

by Chip Mill |

83 Material Sorting Equipment

Separate Fibers, Impurities, Water Pipe

Tube,

Belt, Floor Mat, Zipper

from Plastics |

84 Material Sorting Equipment

Separated Fibers, Impurities, Water Pipe

Tube, Belt, Floor Mat, Zipper

from Plastics |

85 Material Sorting Equipment

Separated Fibers, Impurities, Water Pipe

Tube, Belt, Floor Mat, Zipper

from Plastics |

86 Material Sorting Equipment

Separated Fibers, Impurities, Water Pipe

Tube, Belt, Floor Mat, Zipper

from Plastics |

87 Vertical Mixer

Paddle Type, SMV Series |

88 Vertical Mixer

Spiral Type, SMV Series |

89 Drum Type Mixer SMT Series |

90 Horizontal Mixer SMH Series |

91 Vibration Screening Machine

SXD Series |

92 Metal Separator PEC Series |

93 On Site Usage

Vertical Mixer Spiral Type SMV Series |

94 On Site Usage

Vertical Mixer, Spiral Type SMV Series

with Crusher Conveyer Belt |

95 On Site Usage of

Auxiliary Equipments |

|

|