| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

|

|

Pimpex@RPM supplies energy storage battery cells, energy storage battery cores, energy storage battery boxes, energy storage battery modules, clusters of energy storage batteries, containerized energy storage system, energy storage power station, plus digital energy management platform and fire protection plans, which include optional functions of temperature detection, smoke detection, gas detection, gas fire extinguishing and water fire fighting. Hereinafter is the intro of the manufacturer:

Our company was established in 2019. The headquarters and R&D center are located in Xiamen, Fujian Province. Our company specializes in the development, production and sales of lithium attery cell core materials, lithium iron phosphate energy storage batteries and energy storage systems, and lithium iron phosphate commercial power batteries and systems, with core technology intellectual property rights.

Our company is committed to continuing to be customer-centric, creating the ultimate green energy storage technology products, and providing safe, efficient, clean and sustainable green energy solutions for the global energy supply.

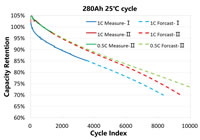

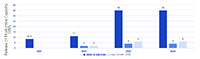

02 Cycle Life of Energy Storage Battery Cell Core 280Ah |

<<< Cycle Life Test Conditions: 25℃, 2.5-3.65V(100%DOD), 0.5C/0.5C or 1C/1C, Cycles Conclusion: After predictive analysis, when the reversible capacity retention rate of the battery is 70%, the cycle times of 0.5C/0.5C are ≥10000 times, and the number of 1C/1C cycles ≥8000 times. |

03 Energy Efficiency of Energy Storage Battery Cell Core 280Ah |

<<< Energy Efficiency Test Conditions: 25℃, 2.5-3.65V (100%DOD), 0.5C/0.5C&1C/1C, Cycles. |

04 Tests Certificates and Certification Standards of Energy Storage Battery Cell Core 280Ah |

<<< Test Certification

|

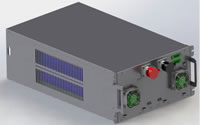

05 Standard Battery Module Specially Designed for Energy Storage Syste and Communication Base Station |

<<< Standard Battery Module

|

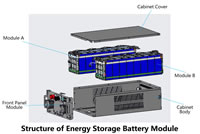

06 Structure of Energy Storage Battery Module - |

<<< Modular Design

|

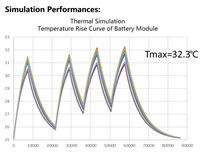

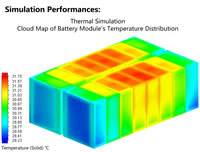

07 Thermal Simulation of Simulation Performances Temperature Rise Curve of Battery Module - |

08 Thermal Simulation of Simulation Performances Cloud Map of Temperature Distribution of Battery Module |

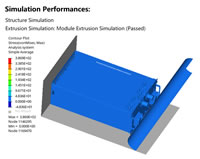

09 Structure Simulation of Simulation Performances Press/Extrusion Simulation Module Extrusion Simulation, Passed |

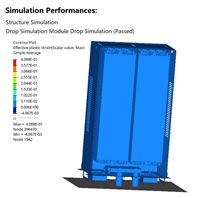

10 Structure Simulation of Simulation Performances Drop Simulation Module Drop Simulation. Passed |

11 Schematic Diagram of Cluster Products of Energy Storage Batteries - |

<<< Battery Cluster Product Description:

Performance Characteristics:

|

12 Schematic Diagram of Standard Cluster of Energy Storage Batteries - |

<<< Battery Cluster Product Description:

Performance Characteristics:

|

13 Schematic Diagram of Products of Containerized Energy Storage System |

<<< Containerized Energy Storage Products Product Description: Features:

Application Range:

|

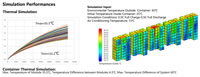

14 Thermal Simulation of Simulation Performances of Products of Containerized Energy Storage System |

<<< Thermal Simulation of Simulation Performances

Container Thermal Simulation: Max. Temperature of Module is 35.5℃, Temperature Difference between Modules is 4.3℃, Max. Temperature Difference of System is 60℃ |

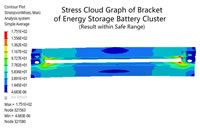

15 Stress Cloud Graph of Bracket of Energy Storage Battery Cluster |

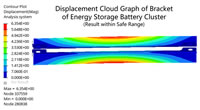

16 Displacement Cloud Graph of Bracket of Energy Storage Battery Cluster - |

<<< Structure Simulation

|

17 Cloud Platform of Energy Storage Power Station Digital Energy Management Platform Webpage |

<<< Cloud Platform of Energy Storage Power Station Cloud Platform:

|

18 Cloud Platform of Energy Storage Power Station Digital Energy Management Platform SCADA Station Management Platform EMS |

<<< SCADA Station Management Platform EMS SCADA Station-Level EMS:

|

19 High Reliability Design Energy Storage System - - |

<<< System with High Reliability Design

|

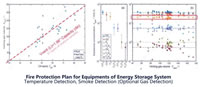

20 Fire Protection Plan for Equipments of Energy Storage System Temperature Detection, Smoke Detection Optional Gas Detection |

<<< Equipment Fire Protection Plan <<< Temperature Detection, Smoke Detection, Optional: Gas Detection

|

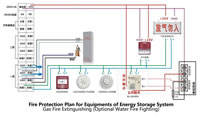

21 Fire Protection Plan for Equipments of Energy Storage System Gas Fire Extinguishing Optional Water Fire Fighting |

<<< Equipment Fire Protection Plan <<< Gas Fire Fighting, Optional: Water Fire Fighting

|

201 Team Size 1000 Employees, 400 R&D Engineers |

202 Land Area 58000 Square Meters |

203 Plant Area 450,000 Square Meters |

204 Investment Quota of 7.7 Billion RMB/CNY |

At the beginning of our business, our company aimed at the market of energy storage's trillion-of-CNY industry, won the support of large fund companies, three major state-owned banks and joint-stock banks, and formed a mature supply chain with upstream and downstream industries to complement each other. Our company was established in 2019 and is located in Xiamen City, Fujian Province. It specializes in the research and development, production and sales of lithium battery cell core materials, lithium iron phosphate energy storage batteries and systems, and lithium iron phosphate commercial power batteries and systems, surely our company has core technology intellectual property rights. Our company is committed to continuing to be customer-centric and providing safe, efficient, clean and sustainable green energy solutions to the world. Mission: -Let Green Energy Benefit All Mankind -Help Strugglers Realize Their Dreams Vision: -Create Ultimate Product -A Career That Makes Life Valued Values: Freedom, Innovation, Sharing and Love |

|

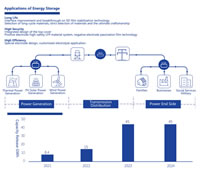

205 Application Scenarios of Energy Storage Batteries |

<<< Power Generation: <<< Transmission & Distribution: <<< Power End Side: |

206 Energy Storage Battery 280Ah |

207 Energy Storage Battery Module |

208 Energy Storage Battery Cluster |

209 Containerized Energy Storage Products |

||||

|

|

|

|

||||

| Key Items | Specification | Key Items | Specification | Key Items | Specification | Key Items | Specifications (40GP) |

| Rated Capacity | 280Ah | Rated Voltage | 51.2V | Rated Voltage | 1280V | DC Rated Voltage | 1280V |

| Charge/Discharge Rate | 0.5P or 0.5C | Rated Power (@25℃,0.5C) |

14.336kWh | Rated Power (@25℃,0.5C) |

358.4kWh | Rated Power (@25℃,0.5C) |

3.584MWh |

| Size (L*W*H) | 173*71*207mm | Size (L*W*H) | 750*424*230mm | Size (L*W*H) | 750*1517*2282mm | Rated Grid Voltage | AC 0.69/10/35kV |

| Energy Density | ≥160Wh/kg | Energy Density | ≥132.7Wh/kg | IP Rating | IP20 | Fire Fighting Method | Heptafluoropropane |

| Cycle Life (25℃, @70%) |

10000cls (0.5P or 0.5C) |

Cooling Method | Air-Cooled | Cooling Method | Air-Cooled | Cooling Method | Air-Cooled |

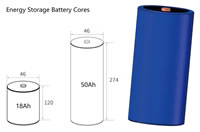

206 Energy Storage Cylindrical Battery |

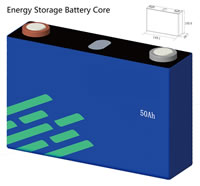

206 Energy Storage Battery 50Ah |

207 Energy Storage Battery Box |

|||||

|

|

|

|||||

| Key Items | Spec.I | Spec.II | Key Items | Spec.I | Spec.II | Key Items | Spec. |

| Rated Capacity | 18Ah | 50Ah | Rated Capacity | 50Ah | Rated Voltage | 48V | |

| Charge/Discharge Rate | 0.5C | 0.5C | Charge/Discharge Rate | 0.5C | Rated Power (@25℃, 0.5C) |

4.8kWh | |

| Size (L*W*H) | D46*120mm | D46*274mm | Size (L*W*H) | 39.7*149.1*100.6mm | Size (L*W*H) | 550.5*483*127mm | |

| Energy Density | ≥150Wh/kg | ≥155Wh/kg | Energy Density | ≥136.7Wh/kg | Energy Density | ≥100Wh/kg | |

| Cycle Life (25℃) | 8,000cls (0.5C@70%) |

8,000cls (0.5C@70%) |

Cycle Life (25℃) | 4000cls (1C@80%) |

10000cls (0.5C@70%) |

Cooling Method | Natural Cooling |

208 Product Certification System of Energy Storage Batteries |

Video of Over Squeeze Test 1-Hour No Explosion No Fire |

Video of Puncture Test 1-Hour, Simulate Short-Circuit Failure within Battery Limit |

| ↑↑↑ Safety Test ↑↑↑ Over Squeeze Press and Extrusion Test Conditions: R=75mm, 5mm/s, OV/deformation 30%/(13±0.78)kN, 10min, 1h Test Results: No Explosion, No Fire |

↑↑↑ Safety Test ↑↑↑ Acupuncture Simulate short circuit failure within the battery limit. Test Conditions: D8mm, 25mm/s, 1h Test Results: No Explosion, No Fire |

209 Intellectual Property Layout and Intellectual Property Risk Control |

<<< Intellectual Property All-Round Intellectual Property Layout:

950+Patents Application, 260+Patents |

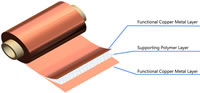

210 Materials Technology Next Generation Current Collector Technology Functional Copper Metal Layer Supporting Polymer Layer Functional Copper Metal Layer |

211 Materials Technology Integrated Injection Technology for Top Cover of Box for Energy Storage Battery Cell Cores |

212 Materials Technology Graphite Coating Technology for Energy Storage Battery Cell Cores - - |

213 Materials Technology PFN Interface Generation Technology for Energy Storage Battery Cell Cores - |

↑↑↑ Next-Generation Current Collector Technology

|

↑↑↑ Integrated Injection Technology for Top Cover

|

↑↑↑ Graphite Coating Technology

|

↑↑↑ PFN Interface Generation Technology

|

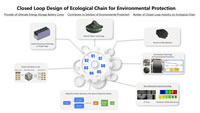

214 Closed Loop Design of Ecological Chain for Environmental Protection |

<<< Closed Loop Design of Ecological Chain for Environmental Protection

1. Material Repair Technology |

215 Test Center for Energy Storage Battery Cell Cores - |

<<< Test Center <<< Future Plan

|

↓↓↓ Material Testing Laboratory - More Than 40 Physical and Chemical Analysis and Testing Instruments - 20 High-End Instruments Such as SEM, XRD, ICP, etc. |

216 Test Center for Energy Storage Battery Cell Cores Material Testing Laboratory Electrochemical Workstation |

217 Test Center for Energy Storage Battery Cell Cores Material Testing Laboratory SEM |

218 Test Center for Energy Storage Battery Cell Cores Material Testing Laboratory Infrared Spectrometer |

219 Test Center for Energy Storage Battery Cell Cores Electrical Performance Laboratory PACK Test Cabinet |

220 Test Center for Energy Storage Battery Cell Cores Electrical Performance Laboratory High and Low Temperature Environment Box |

<<< Electrical Performance Laboratory - Electrical Performance Self-Test Ability 100% - 1300 Battery Charge and Discharge Channels |

221 Test Center for Energy Storage Battery Cell Cores |

222 Test Center for Energy Storage Battery Cell Cores Safety Laboratory Vibration Table |

<<< Safety Laboratory - More Than 30 Safety Test Equipments - Detection Capability: Overcharge, Overdischarge, Drop, Short Circuit, Squeeze/Press/Extrusion, Acupuncture, Thermal Runaway, etc. |

223 Test Center for Energy Storage Battery Cell Cores Energy Storage Joint Debugging Laboratory Lithium Battery Group Feedback Type Charging and Discharging Test System |

224 Test Center for Energy Storage Battery Cell Cores Energy Storage Joint Debugging Laboratory Lithium Battery Group Feedback Type Charging and Discharging Test System |

<<< Energy Storage Joint Debugging Laboratory - 40 Modules and About 160 Pack Channels |

↓↓↓ Manufacturing Capability

|

|||

225 Energy Storage Battery Manufacturing Capability Advanced MES Intelligent System Full Data Traceability in Manufacturing Process |

226 Energy Storage Battery Manufacturing Capabilities Industry Leading Manufacturing Equipments - |

227 Energy Storage Battery Manufacturing Capacity Simplify Process and Reduce Difficulty of Manufacturing |

228 Energy Storage Battery Manufacturing Capacity IATF16949 Quality System Management with 1202 Process Control Points |

229 Project Planning for Energy Storage Battery Cell Cores Manufacturing |

<<< Project Planning for Energy Storage Battery Cell Cores Manufacturing #1 Phase Plant for New Materials #2 Phase Lithium Battery R&D and Intelligent Manufacturing Project #3 Phase Plant |

|

230 Partners on Energy Storage Battery Cell Cores |

|

||||||||||||||||||||||||||||||||||||||||||||

230 >>> Partners on Energy Storage Battery Cell Cores |

|

|

Social Responsibility |

|||

231 Social Responsibility Talent Development Concepts Share with Love Diversified Growth |

233 Social Responsibility Community Development Concept Give Back to Society Progress Together |

232 Social Responsibility Responsible Supply Chain Concepts Fair and Just Win Win |

234 Social Responsibility Sustainable Development Concepts Green Technology Low Carbon Cycle |

300 Employees Engineers Patents Industry Base, Headquarter, Offices  301 Applications of Energy Storage |

Our company was established in 2019, the headquarter and R&D center are located in Xiamen City, Fujian Province, specialized in the R&D, production and sales of lithium iron phosphate core materials, lithium iron phosphate energy storage batteries and energy storage systems, and lithium iron phosphate commercial power batteries and systems. We grasp core technology intellectual property rights. Our company is committed to continuing to be customer-centric, creating the ultimate green energy storage technology products, and providing safe, efficient, clean and sustainable green energy solutions for the global energy supply. Long Life: Interface improvement and breakthrough on SEI film stabilization technology Selection of long-cycle materials, strict selection of materials and the ultimate craftsmanship High Security: Integrated design of the top cover Positive electrode high-safety LFP material system, negative electrode passivation film technology High Efficiency: Special electrode design, customized electrolyte application |

302 Energy Storage Battery Cell Core 280Ah |

<<< Application Scenarios:

|

303 Energy Storage Battery Cell Cores 18Ah, 50Ah |

<<< Application Scenarios:

|

||||||||||||||||||||||||||||||||||||||||

304 Energy Storage Battery Cell Core 50Ah |

<<< Application Scenarios:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

305 Energy Storage Battery Box 3U Chassis, 48V 100Ah |

<<< Application Scenarios:

|

306 Energy Storage Battery Module 51.2V 280Ah |

<<< Application Scenarios:

|

307 Containerized Energy Storage System 20GP 1.2MWh, 40GP 3.58MWh |

<<< Application Scenarios: The containerized energy storage system is an energy storage device that meets the megawatt-level power output requirements and integrates energy storage battery systems, energy management systems, monitoring systems, temperature control systems and fire protection systems.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||

| rubberimpex.com | plasticimpex.com | mouldimpex.com | Loowi.com | GoldenPalaceGate.com | ||

| rubberplasticmould.com | ibmmachine.com |

moldimpex.com |

iLoowi.com | GoldenPalaceGate.cn | ||

| rpm.mobi | isbmmachine.com | masks machines | jindianmen.cn | |||

| wastetiresrecycle.com | printing-machines.cn | hot-stamping-machines.cn | hot-stamping-machines.com | logistics-forklifts.cn |

| Copyright © Pimpex@RPM Since 2002 www.plasticimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |