| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

|

|

Pimpex Plastic cooperates with the manufacturer to supply below equipments from China:

|

ISBM Series Full-Automatic Injection Stretch Blow Molding Machines These machines are full automatic one-step molding machines for thermoplastic materials such as PET, PC and PP. They are widely used for the manufacture of packaging bottles in such industries as pharmaceutical medicines, health care products, cosmetics, foods and condiments, etc. These machines have multi-cavities in one mold which can produce automatically and continuously. They adopt four working stations index head, hot runner system and multi-stage injection molding system. Injection, temperature adjustment, stretch blow molding and product out-feed stations work simultaneously to ensure high efficiency and energy saving operation of the machines. They are preferred equipment for modernized productions.

|

Technical Datas of Automatic Plastic Injection Stretch Blow Molding (ISBM) Machines

Cosmetic Bottles, Pharmaceutical Bottles, Food Bottles, Condiment Bottles |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IBM Series Full-Automatic Injection Blow Molding Machines These equipments are one-step full automatic injection blow molding machines which are applicable to the processing of thermoplastic materials e.g. PE, PP, PS (SAN, PMMA, PC, PETG, PEN). They are widely used in manufacturing packaging bottles for pharmaceutical medicines, healthcare products, foods and beverages, cosmetics and other industries. These machines have multi-cavities in one mold which can perform continuous production full automatically. They adopt horizontal three working stations index head, hot runner system and multi-stage injection molding system. Plastic injection, blowing and stripping stations act simultaneously to guarantee high efficiency and energy saving operation of the machines. They ensure the flatness of bottle mouth and high precision of the internal and external diameter and the thread of bottle neck, without any scrap. They are the standard equipment for modern environment protection productions.

|

Technical Datas of Automatic Plastic Injection Blow Molding (IBM) Machines

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SBM Series Full-Automatic High Speed Rotary Stretch Blow Molding Machines This machine is a full automatic two-steps rotary stretch blow molding machine for thermoplastic materials such as PET, PP etc. It is widely used for the blow molding of plastic container (including hot filling bottle) suitable for the product of water, tea drink, dairy, fruit juice, carbonated beverage and pharmaceutical injection etc. With the structure of multi-mold in one machine, this machine can complete the actions of parison unscrambling, parison feeding, heating, feeding, stretch, blowing, cooling and bottle conveying etc full automatically. The main components on the machine are of international famous brand. The machine owns the advantage of high level automation, reliable and stable operation and low power consumption. It is the high efficient equipment for large scale production in modern scale large enterprise.

|

Technical Datas of Automatic High Speed Rotary Stretch Blow Molding (SBM) Machines

|

|||||||||||||||||||||||||||||||||||||||||

EBM Series Full-Automatic Extrusion Blow Molding (EBM) Machines This equipment is applicable to the production of containers made of copolymers such as PE and PP. It is widely used in beverage, dairy, daily chemical product, food and pharmaceutical industry. This machine adopts internationally advanced industrialized construction design. Main components are of famous international brands. Duplex die, 3-die, 4-die, 6-die, 8-die and 10-die extrusion systems, multilayer co-extrusion system and wall thickness control system can be provided at customer's request, so that the machine can perform the functions of material plasticizing, extruding, blowing and molding, tail and mouth cutting and conveying etc. steadily, high-efficiently and automatically. It complies with the requirement of industrialized and modernized production.

|

Technical Datas of Automatic Extrusion Blow Molding (EBM) Machines

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||

EBM-50 |

|||||||||

Four Die, Center Distance 100mm

|

|||||||||

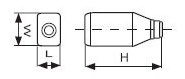

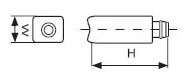

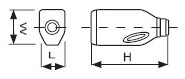

W |

L |

H |

W |

H |

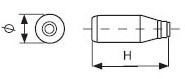

Fi |

H |

W |

L |

H |

90 |

80 |

200 |

90 |

200 |

90 |

200 |

- |

- |

- |

Six Die, Center Distance 70mm

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

60 |

60 |

180 |

60 |

180 |

60 |

180 |

- |

- |

- |

EBM-100 |

|||||||||

Single Die

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

300 |

150 |

280 |

300 |

280 |

150 |

280 |

300 |

150 |

280 |

Double Die, Center Distance 250mm

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

200 |

150 |

280 |

200 |

280 |

150 |

280 |

200 |

150 |

280 |

Three Die, Center Distance 170mm

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

140 |

120 |

280 |

140 |

280 |

140 |

280 |

140 |

120 |

280 |

Four Die, Center Distance 120mm

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

100 |

80 |

280 |

100 |

280 |

100 |

280 |

100 |

80 |

280 |

Six Die, Center Distance 80mm

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

60 |

60 |

280 |

60 |

280 |

60 |

280 |

60 |

60 |

280 |

Eight Die, Center Distance 60mm

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

45 |

45 |

200 |

45 |

200 |

45 |

200 |

45 |

45 |

200 |

EBM-200 |

|||||||||

Four Die, Center Distance 190mm

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

160 |

130 |

200 |

150 |

330 |

150 |

330 |

170 |

150 |

330 |

Six Die, Center Distance 125mm

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

110 |

90 |

180 |

105 |

330 |

110 |

330 |

105 |

150 |

330 |

Eight Die, Center Distance 100mm

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

85 |

80 |

330 |

80 |

330 |

85 |

330 |

- |

- |

- |

Ten Die, Center Distance 80mm

|

|||||||||

W |

L |

H |

W |

H |

Fi |

H |

W |

L |

H |

70 |

60 |

330 |

60 |

330 |

65 |

330 |

- |

- |

- |

| Copyright © Pimpex@RPM Since 2002 www.plasticimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |