| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

|

|

Catalogue of Multi-Colours Injection Moulding Machine, MC Series Energy Saving

Bi-Colors Injection Molding Machines, Servo Energy-Saving MC Series

Bi-Colors Injection Molding Machines, Servo Energy-Saving MC Series |

With a history dating back to 1950s, our factory is one of the earlist manufacturers of plastic injection molding machinery in China, covering a total area of 100,000 sq.m. with main workshop 12,000 sq.m. which is engaged in the installation of whole sries plastic injection molding machines. We mainly produce FT serial economic models, FTA serial with displacement pumps, FIB serial frequency conversion models, FJ serial extruding-injection models, ZJ serial models of injection machines with the clamping forces 40kN-40,000kN and shot volumes 100ml-88,000ml. We also produce PET, PVC, dual colors (bi-colors), CE standard injection machines, etc. Our injection machines have been well sold in China and exported to 40 countries and regions such as Japan, Korea, France, Saudi Arabia and Indonesia. Our factory is ISO9001, CE certificated, and our injection machines are superior in their qualities, we won the state silver medal, the only highest prize in China plastic machinery field. We are one of the strongest, largest and first-class level enterprises in China market of injection machinery. |

18 Bi-Colors Injected Products A |

19 Bi-Colors Injected Products B |

20 Bi-Colors Injected Products C |

21 Bi-Colors Injected Products D |

22 Bi-Colors Injected Products E |

23 Bi-Colors Injected Products F |

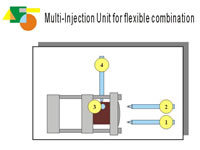

24 Multi Injection Unit For Flexible Combination |

25 Bi-Colors Injection Machine Turn Table Type |

26 Bi-Colors Injection Machine Turn Core Type |

| MACHINE MODEL | UNIT | MC160 | MC250 | ||||

| INJECTION UNIT | A | B | C | A | B | C | |

| Screw Diameter | mm | 28 | 32 | 35 | 32 | 35 | 40 |

| Screw L/D Ration | 24 | 21 | 21 | 21 | |||

| Shot Size (Theoretical) | ml | 70 | 92 | 164 | 92 | 164 | 251 |

| Injection Weight (PS) | g | 64 | 85 | 150 | 85 | 150 | 231 |

| Injection Pressure | MPa | 141.3 | 184.6 | 198.9 | 184.6 | 198.9 | 189.9 |

| Nozzle Stroke | mm | 350 | 350 | 350 | 350 | 350 | 450 |

| Injection Stroke | mm | 115 | 115 | 170 | 115 | 170 | 200 |

| Screw Speed | rpm | 0-245 | 0-245 | 0-245 | 0-225 | 0-225 | 0-225 |

| CLAMPING UNIT | UNIT | MC160 | MC250 | ||||

| Clamping Tonnage | kN | 1600 | 2500 | ||||

| Toggie Storke | mm | 342 | 435 | ||||

| Space between Tie Bars | mm | 705*425 | 795*440 | ||||

| Bearing Capacity of Rotary Platen | kg | 600 | 1100 | ||||

| Max. Mold Height | mm | 435 | 450 | ||||

| Min. Mold Height | mm | 150 | 180 | ||||

| Max. Diameter of Rotary Die | mm | Fi 855 | Fi 935 | ||||

| Turntable Diameter | mm | Fi 735 | Fi 767 | ||||

| Ejector Stroke | mm | 90 | 120 | ||||

| Ejector Tonnage | kN | 28+28 | 28+28 | ||||

| Ejector Number | pcs | 1+1 | 1+1 | ||||

| Distance beween Molds Positoning Centers | mm | 420 | 400 | ||||

| OTHERS | UNIT | MC160 | MC250 | ||||

| Max. Pump Pressure | MPa | 16 | 16 | ||||

| Pump Motor Power | kW | 15.1+15.1 | 18.5+18.5 | ||||

| Heater Power | kW | 5.2 | 6.9 | 7.7 | 6.9 | 7.7 | 9.9 |

| Machine Weight | MT | 7.2 | 8.8 | ||||

| Hopper Capacity | kgs | 28 | 28 | ||||

| Oil Tank Capacity | L | 310 | 430 | ||||

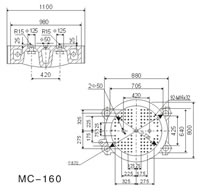

14 Molds Installation Sizes MC160 |

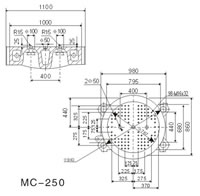

15 Molds Installation Sizes MC250 |

| MACHINE MODEL | UNIT | MC268 | MC400 | ||||

| INJECTION UNIT | A | B | C | A | B | C | |

| Screw Diameter | mm | 32 | 35 | 40 | 40 | 45 | 50 |

| Screw L/D Ration | 21 | 21 | |||||

| Shot Size (Theoretical) | ml | 92 | 164 | 251 | 251 | 350 | 491 |

| Injection Weight (PS) | g | 85 | 150 | 231 | 231 | 322 | 452 |

| Injection Pressure | MPa | 184.6 | 198.9 | 189.9 | 189.9 | 189.3 | 196.6 |

| Nozzle Stroke | mm | 350 | 350 | 450 | 450 | 450 | 370 |

| Injection Stroke | mm | 115 | 170 | 200 | 200 | 220 | 250 |

| Screw Speed | rpm | 0-225 | 0-225 | ||||

| CLAMPING UNIT | UNIT | MC268 | MC400 | ||||

| Clamping Tonnage | kN | 2680 | 4000 | ||||

| Toggie Storke | mm | 465 | 596 | ||||

| Space between Tie Bars | mm | 925*595 | 1020*620 | ||||

| Bearing Capacity of Rotary Platen | kg | 1100 | 1800 | ||||

| Max. Mold Height | mm | 540 | 650 | ||||

| Min. Mold Height | mm | 180 | 300 | ||||

| Max. Diameter of Rotary Die | mm | Fi 1135 | Fi 1225 | ||||

| Turntable Diameter | mm | Fi 931 | Fi 1015 | ||||

| Ejector Stroke | mm | 120 | 140 | ||||

| Ejector Tonnage | kN | 28+28 | 65+65 | ||||

| Ejector Number | pcs | 1+1 | 1+1 | ||||

| Distance beween Molds Positoning Centers | mm | 490 | 500 | ||||

| OTHERS | UNIT | MC268 | MC400 | ||||

| Max. Pump Pressure | MPa | 16 | 16 | ||||

| Pump Motor Power | kW | 18.5+18.5 | 30+30 | ||||

| Heater Power | kW | 6.9 | 7.7 | 9.9 | 9.9 | 12 | 15.9 |

| Machine Weight | MT | 8.8 | 16.3 | ||||

| Hopper Capacity | kgs | 28 | 28 | 40 | 40 | ||

| Oil Tank Capacity | L | 410 | 766 | ||||

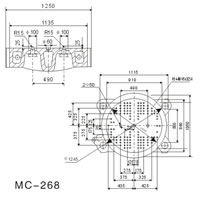

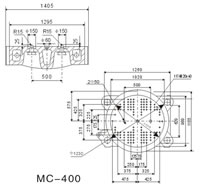

12 Molds Installation Sizes MC268 |

13 Molds Installation Sizes MC400 |

| MACHINE MODEL | UNIT | MC650 | ||

| INJECTION UNIT | A | B | C | |

| Screw Diameter | mm | 50 | 58 | 65 |

| Screw L/D Ration | 21 | |||

| Shot Size (Theoretical) | ml | 491 | 740 | 1012 |

| Injection Weight (PS) | g | 452 | 681 | 931 |

| Injection Pressure | MPa | 196.6 | 183.1 | 182.9 |

| Nozzle Stroke | mm | 370 | 370 | 430 |

| Injection Stroke | mm | 250 | 280 | 305 |

| Screw Speed | rpm | 0-185 | ||

| CLAMPING UNIT | UNIT | MC650 | ||

| Clamping Tonnage | kN | 6500 | ||

| Toggie Storke | mm | 848 | ||

| Space between Tie Bars | mm | 1420*870 | ||

| Bearing Capacity of Rotary Platen | kg | 3000 | ||

| Max. Mold Height | mm | 840 | ||

| Min. Mold Height | mm | 350 | ||

| Max. Diameter of Rotary Die | mm | Fi 1575 | ||

| Turntable Diameter | mm | Fi 1300 | ||

| Ejector Stroke | mm | 350 | ||

| Ejector Tonnage | kN | 110+110 | ||

| Ejector Number | pcs | 1+1 | ||

| Distance beween Molds Positoning Centers | mm | 700 | ||

| OTHERS | UNIT | MC650 | ||

| Max. Pump Pressure | MPa | 16 | ||

| Pump Motor Power | kW | 22+18.5+18.5 | ||

| Heater Power | kW | 15.9 | 22.3 | 26 |

| Machine Weight | MT | 22.3 | ||

| Hopper Capacity | kgs | 40 | 50 | 50 |

| Oil Tank Capacity | L | 1400 | ||

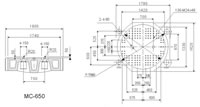

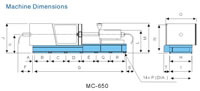

07 Molds Installation Sizes MC650 |

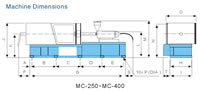

05 Machine Dimension MC250 MC400 |

06 Machine Dimension MC250 MC650 |

L = Hopper Dryer Reference N = Robot Arm Reference Q = Mounting Hole Diameter |

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | |

| MC250 | 120 | 1060 | 1060 | 1060 | 1290 | 535 | 4700 | 960 | 1012 | 1830 | 1330 | 1430 | 2046 | 1680 | 1470 | 24 | - | - | 388 | 420 |

| MC400 | 120 | 1520 | 1520 | 1120 | 1480 | 670 | 5811 | 1250 | 1310 | 2247 | 1557 | 1667 | 2307 | 2054 | 1855 | 24 | - | - | 456 | 450 |

| MC650 | 115 | 1250 | 1250 | 1250 | 1150 | 1159 | 7430 | 1740 | 1800 | 2360 | 1490 | 1620 | 2320 | 2165 | 2450 | 24 | 1150 | 1150 | 536 | 450 |

MC Series Standard Features: A. Control Unit: B. Clamping Unit: |

25. 3 separated mould opening speed and pressure C. Injection Unit: D. Others: |

MC Series Optional Features: B. Clamping Unit |

C. Injection Unit D. Others |

| Remarks: 1. Due to continual improvements, the specifications are subject to change without notice. 2. Actual figures of the specification mentioned may vary from the final machine configuration. Please contact us if you require more specified datas. 3. Speed related specifications are based on theoretical datas. 4. Theoretical shot volume is the cross sectional area of cylinder multiplied by the stroke of screw. 5. Shot weight is applicable for GP-PS material and variable according to the grade of resin, molding conditions and mold. 6. Plasiticizing capacity is applicable for GP-PS material. 7. Actual plasticizing capacity is not less than 80% of the theoretical data. |

|

Go Back Various Pricings for Plastics Related Projects Center

| Copyright © Pimpex@RPM Since 2002 www.plasticimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |